Projection Welding

Questions and Answers

The first step in developing a process is to know what is to be welded. In this case we are using stainless steel. From this we know that we have a strong, resistive material. Depending upon the material grade it could be subject to embrittlement, if it cools too quickly.

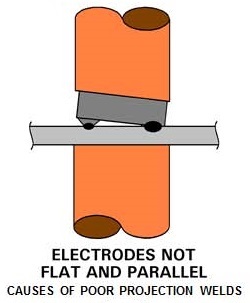

Let’s not get ahead of ourselves. Several machine set up items must be addressed before the schedule is developed. In projection welding normally several projections or even a full ring projection are being welded at the same time. For this to occur successfully the tooling and machine have to be set up properly and operating efficiently. Important factors are:

FORCE APPLICATION AND FOLLOW-UP

ALIGNMENT

PROJECTION SHAPE, SIZE & CONSISTENCY

ELECTRODE MATERIAL AND CONFIGURATION

TO-5 cans are hermetically sealed metal transistor assemblies. The leads exit the package through glass insulators. The bottom plate is assembled to the can by forming a continuous ring projection weld around the lip of the lower plate.

It is important not to damage the glass seals on the leads during assembly. Damage to the glass seals will occur if heat or distortion reaches the area of the glass to metal seals.

To prevent damage the following can be addressed:

First: Design the electrode to insure that current flow does not flow through the glass area of the lower plate. Keep the current flow in the periphery.

Secondly: It is important that the tooling be aligned to bring the full periphery of the part in full contact at the same time to prevent distortion of the lower plate. If the plate distorts the glass seals likely will fail and crack.

Third: If the machine does not have proper follow up – as the projection start to collapse the upper cylinder must maintain full direct force on the part. If there is a delay the full force could come after the nugget is cooling and distortion may occur. Again the plate may distort.

Fourth: The bottom electrode should support the full bottom plate to prevent the possibility of distortion. The current will flow in the periphery while the rest of the plate is supported. This helps to maintain flatness and keeps the glass to metal seal areas cool.

Fifth: Both upper and lower electrodes should have some form of cooling.

Electrode material selection – RWMA Class 2 would be the first choice. If it wears faster than desired then go to RWMA Class 3. I don’t think this application would need RWMA Class 11 which would be the next step up in wear resistance.

For additional information see ARTICLE:

ARE THERE ANY CONCERNS USING DISSIMILAR ELECTRODE MATERIALS TO WELD TO-5 CANS?

Reference: CMW Inc. Catalog

Tuffaloy Products Catalog

RWMA: Resistance Welding Manual, 4th Edition, Section 3

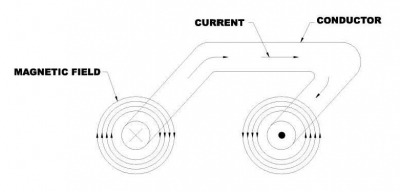

It is a law of physics that current flowing through a conductor will generate a flux field around it. This flux field is a magnetic field and is the basis of electric motors, generators, and transformers.

MAGNETIC FIELD AROUND ELECTRICAL CONDUCTOR

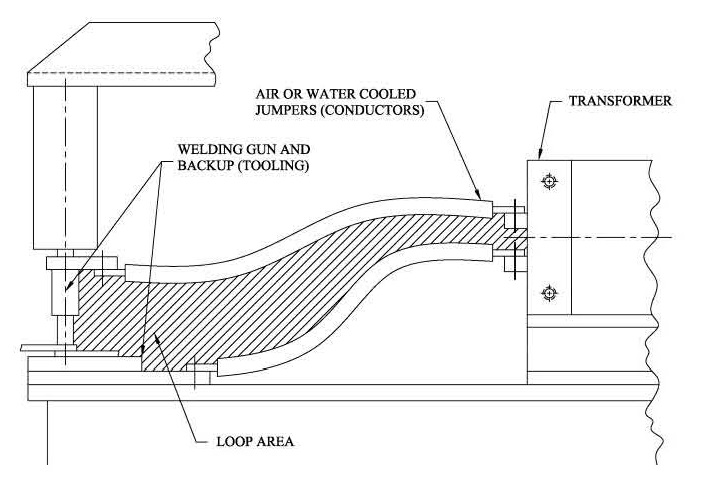

All resistance welding machines have this flux field in the throat or loop area.

THROAT OR LOOP AREA WITH MAGNTIC FIELD

Any magnetic material that enters this throat area will be affected by the magnetic field, if this is an AC machine. DC or MFDC machines still have magnetic affects but do not have the reactance of an AC machine and will not cause the part to heat up and drain the power from the weld.

Another issue is that as the welding machine initiates it could cause parts indexing into the throat of the machine to move if they are not held in the fixture properly. Tooling must hold parts tightly to prevent them from moving as the magnetic field builds and collapses while the parts are moving into the throat. The magnetic field is a given. It will not go away.

Over time weld flash builds up on the frame and tooling. If it is not removed it can build up heat and drain the power of the welder. Stray current paths can occur in the weld flash build up and unusual operations can be noted. This can be solved by preventive maintenance and weld flash removal.

References: RWMA Resistance Welding Manual 4th Edition

AWS J1.2 Guide to Installation and Maintenance of Resistance Welding Machines

Many parameters if not controlled could be a factor and lead to cracks in or near a projection weld.

MATERIAL: The material being welded is one factor. It could be a brittle material after nugget formation without a tempering or post heat treatment operation. The material might be one which tends to form voids if not forged during the weld to heal those voids. This could be a brittle material that must be annealed with post heat treatment after nugget formation. The cracks could form in the weld or around the periphery without treatment.

TOOLING or PART ALIGNMENT: If the projections do not contact the part all at once, those in contact will carry too much power and others none. Those with too much power may expel metal. As set down occurs the others will make contact. Then likely will arc upon contact. Expulsion occurs again. Any or all of these welds could show discrepancies.

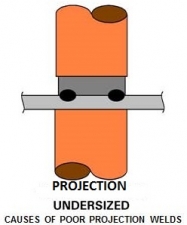

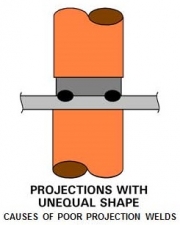

PROJECTION SIZE AND SHAPE: If projections are not equal in size some which are short in height will make contact after other and have the power problem described in alignment. If they are equal height but different size/diameter they will collapse at different speeds. This will steal the power from those that have not set down and last projections to make contact may be weak and fail.

UNEQUAL SIZE UNEQUAL SHAPE

FOLLOW-UP: If all is otherwise good the machine must be able to deliver continuous full force as the projections collapse. Large massive press welders may have an inertia in their massive cylinder heads. This is a delay factor. Due to this inertia the cylinder may hesitate just when the cylinder needs to drive the hot projection down and forge it. This leads to nuggets with cracks or weak joints. This same situation could be caused by a faulty servo or cylinder. Machine maintenance, low-inertia-machines or fast-follow-up holders are the correction for this condition.

V

V

LOW INERTIA MACHINE FAST-FOLLOW-UP HOLDER

WELD SCHEDULE: The proper weld schedule for the material being welded is always necessary. Weld schedules with the appropriate pre and post treatments must be chosen when required to insure the formation and forging of a strong nugget. A source of projection weld schedules is AWS C1.1.

Another article in this blog on this subject is:

What are the Do's and Don'ts for projection welding?

Reference: AWS C1.1- Recommended Practices for Resistance Welding

RWMA - Resistance Welding Manual 4th Edition

There is not a lot of data published on projection welding. There is a table published by AWS in their specification AWS C1.1 Recommended Practices for Resistance Welding. Table 48 lists process requirements for cross wire welding hot and cold drawn steel wire. It should do well as a starting point for this application.

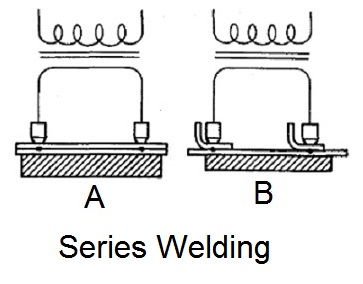

In a series weld generally an upper gun puts power in through one weld point which travels through that joint into a common lower platen. The power flows through this platen to the location of the second weld and then through this weld to the second weld gun and back to the transformer. Two welds are made with one operation. Care must be taken to keep the welds separated to avoid shunting currents. Shunting currents are currents that do not flow through the desired weld joints.

In the given wire welding situation 4mm wire replaces the upper piece. Spacing must be adequate to avoid current flow through the wire. Then using the chart in C1.1 try the lowest set down listed at 15% for your wire size. Take those values and reduce the power by 30 to 50% and see what happens for the first trial welds. Then adjust up or down on the settings until something happens. If nothing happens at 15% set down settings go to 30% settings and try the same process again.

Always approach from safe low power setting to make sure that part, people and equipment are safe in this trial and error scenario.

The values listed in C1.1 will make a weld for the material listed. Your material and equipment may vary but a weld can be made at similar settings.

Reference: AWS C1.1 Recommended Practices for Resistance Welding

RWMA Resistance Welding Manual 4th Edition

Page 9 of 14

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.