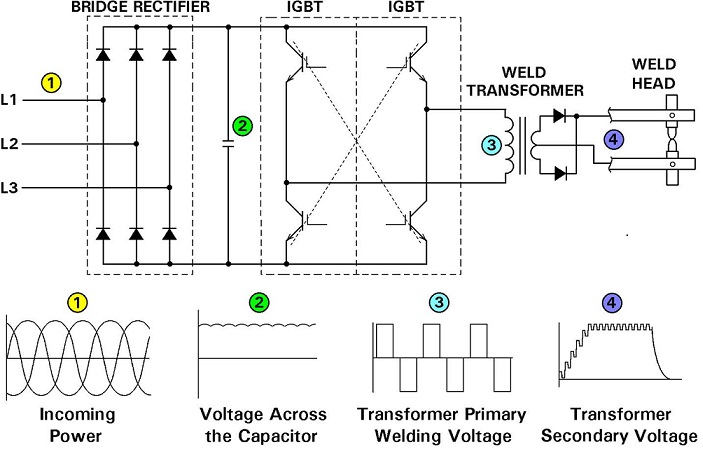

MFDC stands for MID FREQUENCY DIRECT CURRENT. Three phase AC @ 60 hertz input is converted to a high frequency 400-4000 Hz input to the transformer. The transformer then produces a DC output to the welder.

SCHEMATIC AND POWER CONVERSION IN CONTROL AND TRANSFORMER OF MID FREQUENCY INVERTER

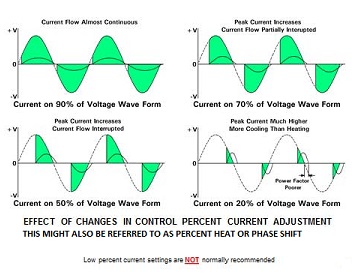

AC stands for alternating current. Historically in North America the standard welding controls have been single phase AC @ 60 Hz input. The transformer produces a low voltage high amperage AC output at 60 Hz suitable to produce the desired welding parameters. The Typical AC sine wave outputs would look like those shown below.

Each time the sine wave crosses zero the AC weld actually cools momentarily. Additional cooling occurs depending upon the amount of phase shift as shown above. As the heating accumulates the part heats up. AC equipment is very robust and can last a lifetime if properly cooled and operated within its rated capability.

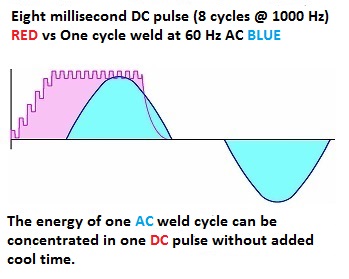

MFDC is timed in milliseconds (ms). There are 16 ms in one 60 Hz AC sine wave. Because MFDC heats continuously, DC actually can produce the same amount of heat of one AC sine wave in much less time as demonstrated below:

This attribute of heating without a zero cross over and no phase shift allows MFDC to heat quickly. Another feature is that inductive losses are nearly eliminated with DC. Therefor MFDC transformers can heat the parts with less power. Additionally MFDC transformers are operated at higher frequency’s which allows them to be made smaller. Smaller means less weight for a robot arm to carry.

MFDC has become the system of choice in the automation world. Timing in (ms) allows finer control of the process which can result in better process results.

Many applications are turning to MFDC because the process can:

Lower weight

It is fast

Reduce power requirements

Better resolution of heat control

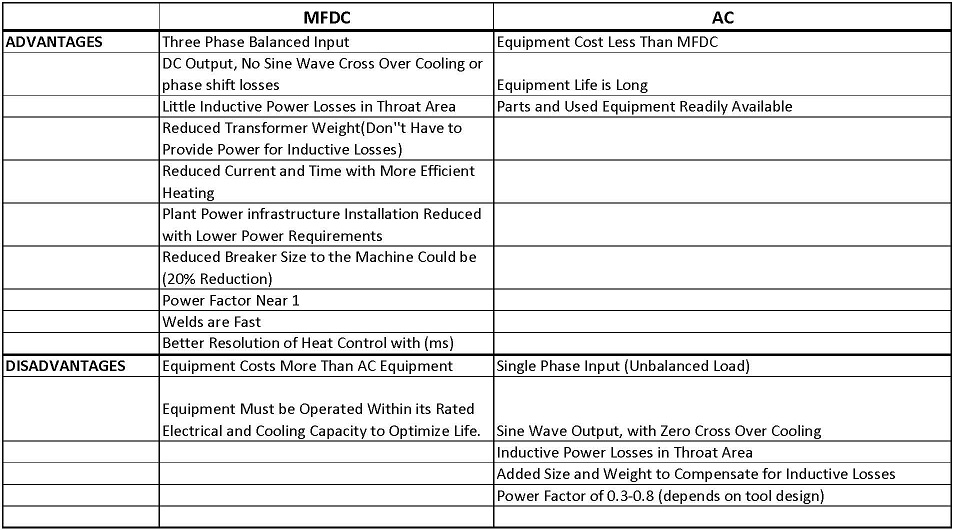

Every operation is different but the principles are the same. When comparing the two processes one could expect to find the following

ADVANTAGES AND DISADVANTAGES:

ADVANTAGES AND DISADVANTAGES OF MFDC AND AC

Many applications continue to use and specify AC equipment. MFDC has become the preferred product being used for automated equipment.

Additional information can be found in:

Is DC or MFDC better than AC in spot welding?

Reference: RWMA – Resistance Welding Manual 4th Edition

AWS – Welding Journal, Q & A July 2019