Controls & Transformers

Questions and Answers

This question has already been answered by another article in this blog:

“HOW DO YOU SIZE A RESISTANCE WELDING TRANSFORMER?”

Please refer to the above article for the answer.

Robot transformers are very robust. They can last for years, if water cooled properly and operated under their rated duty cycle. Overheating a transformer damages the internal insulation and will lead to a short between the primary and secondary coils. Exceeding or running at the rated duty cycle will shorten the life of the diodes in the system.

There are many published resistance welding schedules available for many materials from many sources. In North America the most complete and easily obtained document is an American Welding Society Standard:

AWS C1.1 “Recommended Practices for Resistance Welding”

This document has over forty weld schedules for various materials and processes. They were developed for AC. Twenty-seven of these schedules have a footnote addressing MFDC*.

*FOR DC WELDING EQUIPMENT LOWER CURRENT SETTINGS MAY BE APPROPRIATE

For comparison, there are very few published schedules at this time for MFDC. In fact, development of schedules specifically for MFDC may not happen since all published schedules are used as examples of starting point value “targets”. They are not meant to be dialed in and used as exact values. Industry has learned that the current AC schedules have served well as targets for MFDC equipment.

Sometimes increasing the current and weld time seems to hit a wall as far as nugget growth goes. It is very difficult to grow a nugget larger than the face size of the electrode.

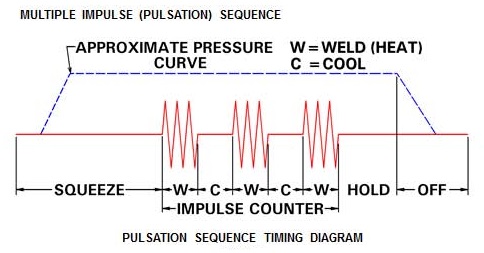

A method that some find successful to increase the face size is to use weld impulses. At the end of the weld cycle schedule an off period of one or two cycles then repeat the weld schedule. The length of the impulses may need to be adjusted to prevent overheated and expulsion.

A larger electrode face size is also an option. This will require a completely new weld schedule. The larger weld face will encourage a larger weld nugget.

Reference: RWMA – Resistance Welding Manual 4th Edition

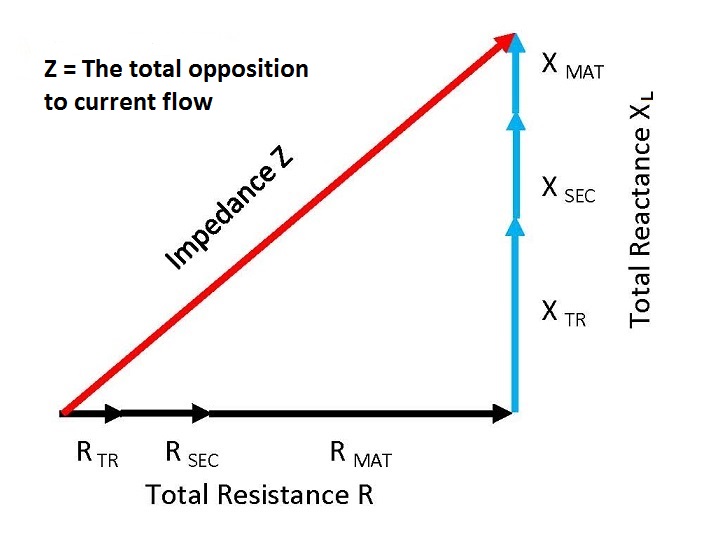

In resistance welding there is opposition to current flow. This is especially true in AC welding systems. The total opposition to current flow is IMPEDANCE. Impedance is made up of two components resistance and reactance.

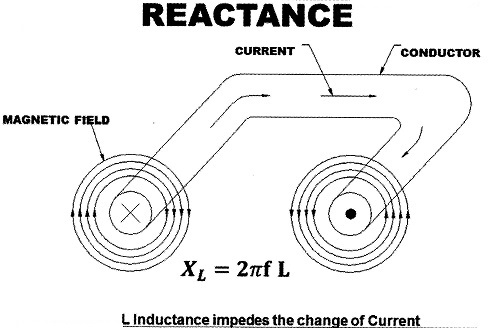

Reactance (X) is basically only present in AC circuits.

Reactance (X) is created by the induced magnetic field around the conductors in the secondary.

This induced field wants to stay in a steady state but in AC, current is constantly changing (reversing from positive to negative) with the AC sine wave. The Reactance builds momentum in each half cycle and resists changing to the other direction. The stronger the magnetic field the larger the reactance. The size of the welder throat is a factor in determining this magnetic strength. Larger throat areas create stronger magnetic fields.

Page 10 of 40

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.