Tooling and fixtures are used in virtually all resistance welding operations to hold parts in place for welding. They must be kept clean of flash and debris and be safe for operators. Heat buildup should be minimized. If a fixture is heating up several possible reasons come to the forefront: Inductance, Insulation, weld flash and location.

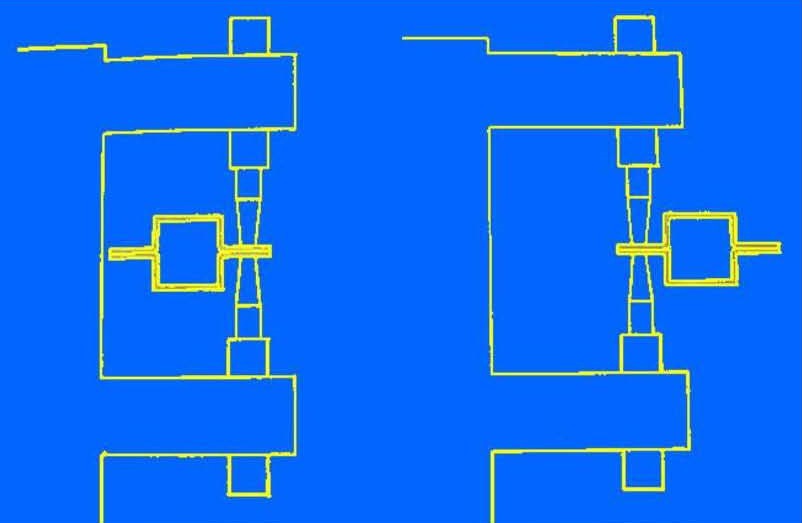

BAD GOOD

This exhibits the part in the throat area but magnetic tooling in the throat causes the same problem. It absorbs energy and heats up during the welding process and forces the welder to work harder to make the desired spot weld.

Inductance is an electrical field induced in any magnetic material in or near the throat of an AC resistance welder. Insulated or not any magnetic material in or close to the throat of the AC machine can be affected. It will absorb energy and heat up. This includes the fixture itself or its components (bolts & nuts). This extra power is wasted heating the fixture and causes the machine to run harder than otherwise required. All the electrical components (cables, shunts, transformers and scr’s) are working harder than necessary to heat this tooling. To prevent this, fixtures should be fabricated from nonmagnetic materials (aluminum, copper, nonmagnetic stainless or insulators). Inductance is a common problem in the field. Many tool rooms are not aware of the problem (inductance). To check your tool, test your tool or components with a magnet to see if it is fabricated with magnetic material.

Insulation of the fixture is also necessary to prevent any current from flowing through the fixture and heating it up by resistance heating. This means insulating bolts, nuts, and washer with washers and sleeves as well as the mating surfaces underneath or between.

The other housekeeping issue is weld flash. A buildup of weld flash can lead to current flow on an otherwise insulated fixture. A stray current path of this sort can lead to heating of the fixture and loss of power at the welding operation.

The proximity of the fixture to the welding should also be considered. Normally the electrodes handle the greatest heat and cooling functions. If the fixture is too close it may come in contact with large amounts of heat and it may also need some form of heat dissipation. This could be a chill block or water cooling.

Weld Fixture Exhibiting Non Magnetic Stainless Tooling and Insulated Pins and Tools with Water Cooling

Reference: RWMA - Resistance Welding Manual 4th Edition, Chapter 19

AWS J1.2:2016 Installation and Maintenance of Resistance Welding Machines