This answer to this question is in another article published in this blog copied in full below:

“HOW DOES A TRANSFORMER CONVERT VOLTAGE AND CURRENT?”

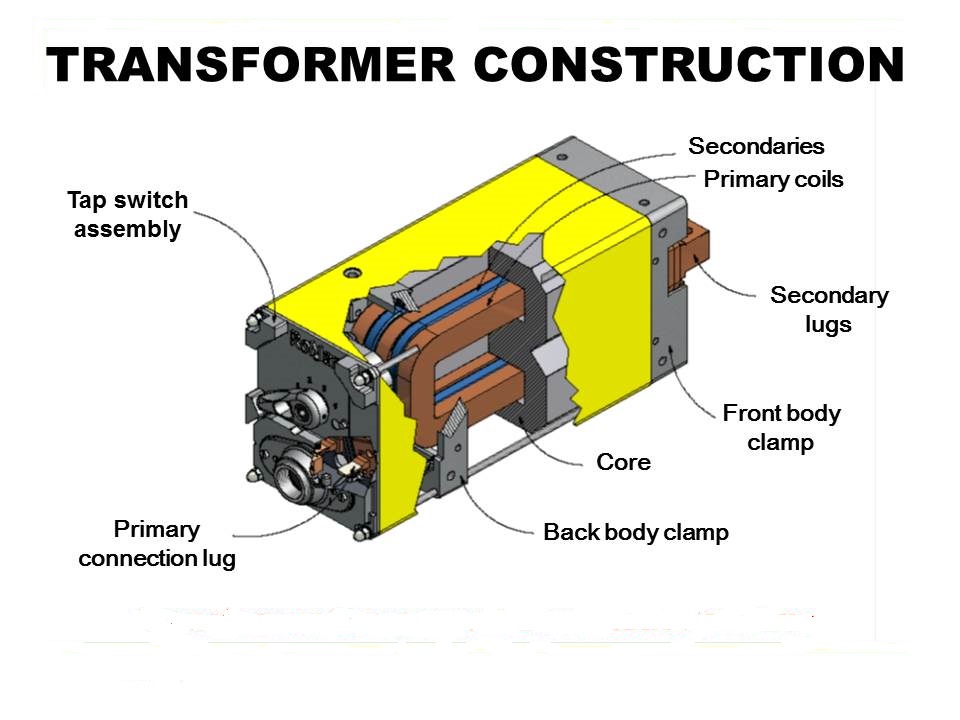

A transformer has no moving parts. Yet they can convert voltage and current to different levels – HOW? In resistance welding high voltage/low amperage input are converted it into low voltage/high amperage output.

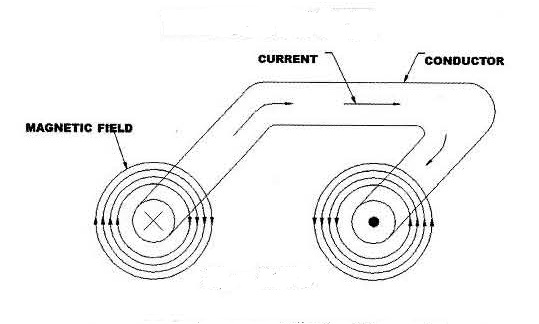

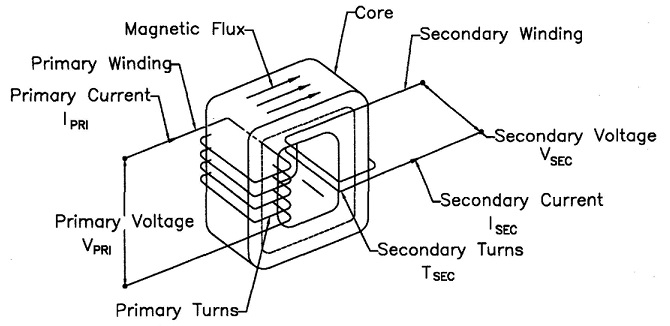

This conversion is made by winding two separate conductors around a common iron core. Applying an alternating voltage to the primary conductor produces current which sets up a magnetic field around itself. This is known as mutual inductance.

The magnetic field in the primary conductor creates lines of magnetic flux in the iron core. This magnetic flux in the core is what links the turns of the two windings. When the lines of the magnetic flux flow around the core, they pass through the turns of the secondary conductor inducing a voltage on the secondary winding. This secondary voltage is what produces the welding current based on Ohm’s Law.

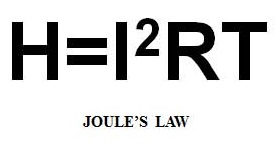

The transformer change in voltage and current allows the power company to deliver economical electrical service to the machine. The transformer then steps the voltage down to a personnel safe voltage and the current up to that necessary to generate the heat from Joule heating:

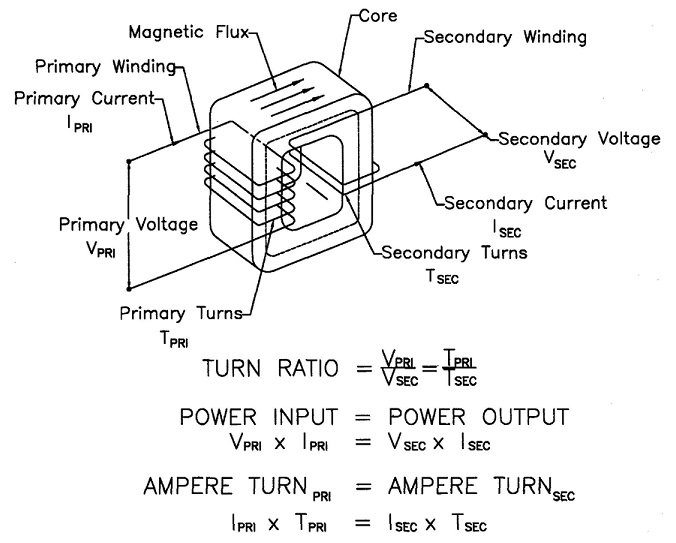

The change in the Voltage/Current in the primary to the Voltage/Current in the secondary is determined by the TURNS RATIO, see article “What is transformer turns ratio?”. In simple words, turns ratio is the number of turns in the primary coil vs the number of turns in the secondary coil.

These same conversions apply in all transformers. Some transformers have tap switches on the primary side. This allows one to change the turns ratio to vary the output voltage and amperage. In resistance welding high voltage low current is brought to the machine which is transformed to low voltage 2-25 volts and 5000 to 90,000 amps.

Transformers conduct a large amount of power. Water cooling is necessary to dissipate the heat. This is important to keep the transformer from overheating and failing.

Reference: RWMA Resistance Welding Manual 4th Edition, Chapter 19

AWS J1.2:2016 Guide to Installation and Maintenance of Resistance Welding Machines

How to Resistance Weld Article: “What is transformer turn ratio”