To answer this question the first assumption is that the question is not concerned about a fixture or holding type clamp. The question is directed towards the electrodes on the welding gun or press welder that closes on the part and hold it in place to deliver the current and force and forge the weld. This answer will talk about the copper alloy used as the resistance welding electrode materials.

In other articles RWMA Group A Class 1, 2, 3, 4 are described. In addition RWMA Group B Class 20 is described. With the exception of the Class 4 all are used regularly as electrode materials in various applications. Their properties vary and it is their properties that decide their use in the various applications. The more conductive materials, Class 1 find applications where conductivity is most important. The stronger materials are applied where strength is the overriding factor, Class 3. Class 2 is used in most applications, which are steel. It is a middle of the road material with good conductivity and strength.

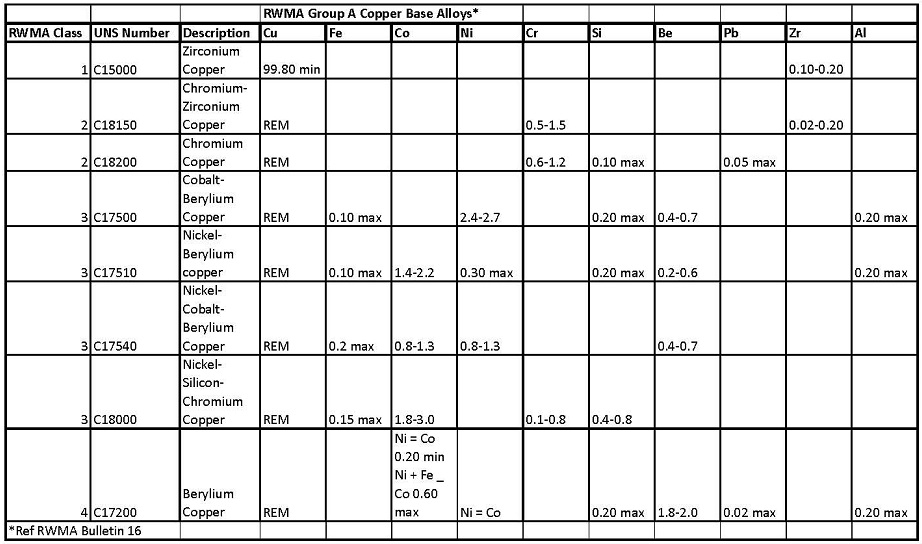

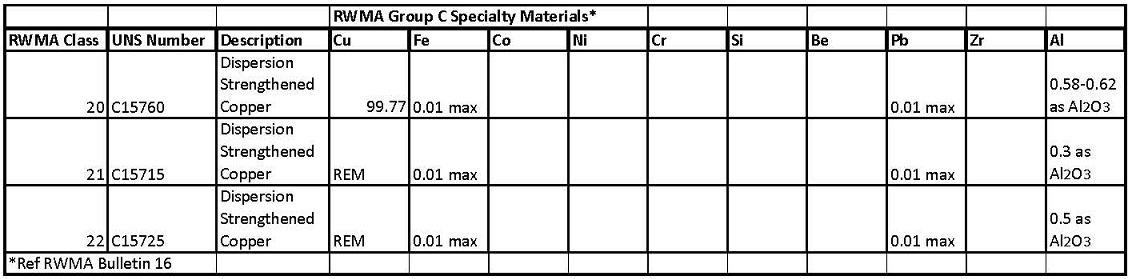

The compositions and properties of these materials are specified and or published by the manufacturers and industry standards such as ASTM and Copper Development Association. Below is some chemistry data:

Reference: RWMA Bulletin 16