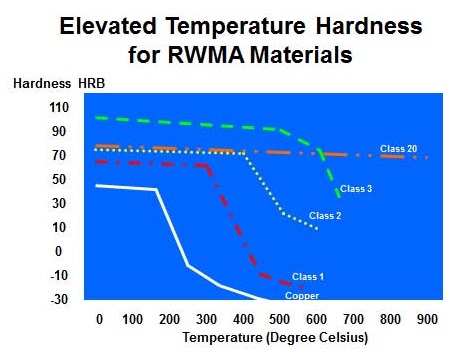

In North America the most commonly used electrode materials for galvanized steel are RWMA Class 1, 2 and 20. By the quantity Class 1 and 2 are the most popular by far. Class 20 finds applications where the fabricator has weld schedules that make use of its unique properties – good conductivity and high heat resistance. Class 20 is sold at a premium for its higher heat properties.

In a previous article there is a complete discussion of this topic:

“WHY IS RWMA CLASS 20 USED FOR SPOT WELDING GALVANIZED STEEL?”

If you don’t operate at high heat RWMA Class 20 may not be needed. Most of industry can operate with RWMA Class 1 & 2 when spot welding galvanized and coated steels. There is no single material that is the best material for spot welding galvanized steel. The weld schedule that is being used decides how much heat is being generated and in turn will influence the electrode material choice.

A second consideration is what other alloys are already in the facility. Standardizing on one alloy is logical if schedules can be adjusted to make this happen. One alloy might prevent alloy confusion one day down the road.

Reference: RWMA – Resistance Welding Manual 4th Edition

AWS Standard C1.1 - Recommended Practices for Resistance Welding

AWS J1.3 - Specifications for Materials Used in Resistance Welding Electrodes and Tooling