Spot Welding

Questions and Answers

It is a common practice to dress resistance welding caps used in robotic and job shop applications. Many dress at breaks or shift changes. In automated operations some dress a very small amount between each part as the line moves. The goal is to maintain a relatively consistent electrode face welding the part. At some point a limit to the material removal is reached and the cap must be changed. The question is:

How much material can be removed before the cap will fail to function?

The assumption is that the dressing removes all surfaces problems and the part is functional. The only consideration is face to waterhole material thickness. Obviously dressing into the water hole is too far. In a nonscientific test observed personally, it was pointed out that the facing thickness is the controlling factor.

When the face thickness is not strong enough to withstand the weld force being applied the electrode face will collapse. Electrode or cap dressing must end before this. Obviously this face thickness can be affected by the face design of the cap or electrode.

Many end users specify a dressing ring on the cap. Some companies have standard parts with the dressing rings as standards. Some of the rings are limits. Other rings mark the water hole. The actual testing and verification of their functionality is beyond the scope of this blog.

Reference: RWMA – Resistance Welding Manual 4th Edition

This combination of very thin brass a very conductive material to a strong, resistive stainless material is very difficult. The brass due to its conductivity will be slow to heat up. The stainless will heat up and probably conduct heat into the brass. Since the brass is so thin it will suddenly overheat and melt through.

If any, there is a very small window for success.

Most modern controls have current feedback and monitoring capability built in. They read and report each half cycle or millisecond depending upon the system being used. Older equipment may not have these features. The use of a monitor offers data confirmation, storage capacity, off-loading capability and security.

HAND HELD CURRENT METER

DeskTop Current Monitors with more features are readily available.

The resistance made when the electrode touches the workpiece is created by:

• Composition of the workpiece

• Surface condition of the workpiece – rough, smooth, clean, dirty

• Conductivity or resistivity of workpiece surface

• Composition of the electrode

• Surface condition of the electrode – rough, smooth, clean, dirty

• Conductivity or resistivity of the electrode surface

• Pressure or force of the electrode on the workpiece

Sandblasting has a dramatic affect upon the surface condition of the workpiece. Depending upon the media used for sand blasting the surface resistance can be a problem?

The weld gun pressure is used for two main reasons to hold the parts together tightly during the weld and to provide forging action during the weld and cool down phase. The hold together includes containing the weld nugget and flash from the faying surfaces and the electrode contact areas. Any adjustments to pressure would be made to facilitate these functions and improve or lengthen the life of the electrodes.

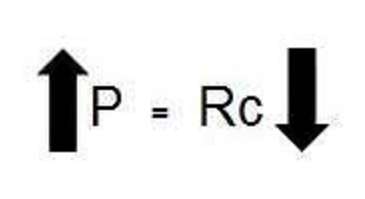

One must always remember that for every action there can be reactions. A change in the pressure can change the heat being generated and thus cause the nugget formation to increase or decrease. This is discussed in an article in this blog titled:

HOW WILL TOO MUCH PRESSURE AFFECT RESISTANCE WELDING?

This article demonstrates that increasing the pressure will decrease the contact resistance. Therefor with the same current flow the total heat in the part will decrease. If the heat is decreased the nugget size will not grow and it is likely going to decrease in size. If the goal was a smaller nugget increasing pressure might work.

If one were to decrease the voltage at the same time by dropping the transformer tap or adjusting the control settings, this would reduce the current flow. Now we have lowered the total current and the resistance is lower due to the increased pressure.

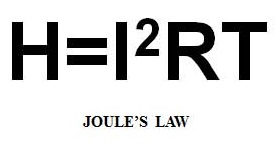

Joules law states that heat is generated by:

Lowering the current and resistance at the same time would greatly decrease the heat being generated at the faying surface. Lowering the voltage when the pressure is increased is not a good parallel adjustment. Increasing the voltage might be a better move if the nugget needs to be maintained after the pressure change.

Adjustments to pressure may be necessary to maintain proper containment of the parts. If the pressure changes affect the weld nugget then changes to the current would be necessary to compensate. To drive more current more voltage would be required.

If indentation is excessive maybe less pressure might be applied. If the nugget is not affected all is good. If the nugget is out of tolerance after the pressure adjustment, then adjustment to the current might be needed to maintain proper nugget size.

References: RWMA – Resistance Welding Manual 4th Edition

Page 9 of 44

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.