Assuming the two workpieces being seam welded are the same, then two different diameter wheels will make contact with the part over two different surface areas. If the surface areas are different, the side with the larger area could run cooler than the other and the nugget will tend to form in the other half of the part with the smaller surface area. Therefore the smaller wheel with the same face geometry will run hotter than the larger diameter wheel. Depending upon the part being run and the process this diameter differential may or may not be enough that action needs to be taken. There are many factors going on during a seam weld that may minimize this variation.

If the diameters should be addressed to correct the issue, then this becomes a simple case of heat balance. The large wheel side is too cold or the small wheel side is too hot. One can address this from either side. Remember if you are making changes in weld faces, it is best to change just one at a time and measure results before making additional changes.

On the large wheel side the face contour could be dressed to a smaller width and leave the wheel thickness as is (Or reduce the wheel thickness and contour). If the wheel hubs are the same the used upper wheel could eventually be moved to the lower side and adjust the contour as needed. The smaller wheel surface on the larger wheel will increase the heat on the large wheel side and pull the nugget toward the faying surface.

On the small wheel side the contour could be adjusted to a larger width to increase the surface area. This will cool this side down and move the nugget toward the faying surface. Depending upon the welding parameters there may have to be a corresponding adjustment in force and current.

In either scenario the heat is moved to the faying surface and the nugget is formed in the proper location and good parts are produced.

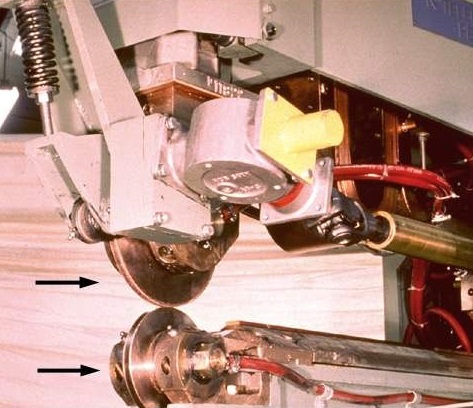

SEAM WELDER WITH TWO DIFFERENT DIAMETER WHEELS

Reference: RWMA – Resistance Welding Manual Section 4