A seam welder has the same components as any other resistance welder. They require the same water cooling as all resistance welders. Water or other similar fluid is a must to perform the cooling of these critical machine components. These components are:

• Transformer

• Conductors

• Control

• Electrodes

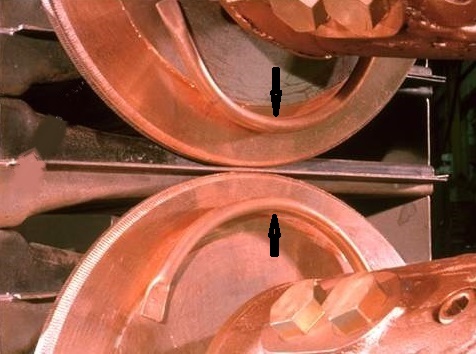

In the case of the seam welder the electrode is a seam welding wheel water cooled at the central hub. Some applications generate excessive heat at the weld area and demand the use of external flood cooling directly at the weld joint.

ARROWS INDICATE EXTERNAL FLOOD COOLING TUBES

The question raised is: Can compressed air be substituted for water?

Water as compared to air at a minimum is fifty times more heat conductive than air. For the machine components it is doubtful that a machine manufacturer would warrant a machine cooled with air. Water must be used for the machine.

If a part producer chooses to externally cool the wheel weld face and part with air, that is up to the producer and his customer and the quality specifications required. Many parts are not externally cooled. It depends upon the amount of heat generated. Air may work?

Water flood cooling is messy but it works.

FOR ADDITIONAL INFORMATION REFER TO OTHER ARTICLES IN THIS BLOG:

“WHAT IS THE PROPER AMOUNT OF WATER COOLING FOR SEAM WELDING?”

“IS THE WATER USED FOR SEAM WELDING HARMFUL AFTER BEING USED FOR COOLING?”

References: RWMA- RWMA Resistance Welding Manual 4th Edition

AWS- AWS Standard J1.2 Guide to the Installation and Maintenance of Resistance Welding Machines