Tapered electrodes are the most used system for attaching electrodes to their holders/tooling in spot welding. Tapers are frequently used in projection welding for attachment. The ease of changing electrodes is the reason for this. As long as the electrode can be removed by a simple twist of the removal tool tapers are the best choice.

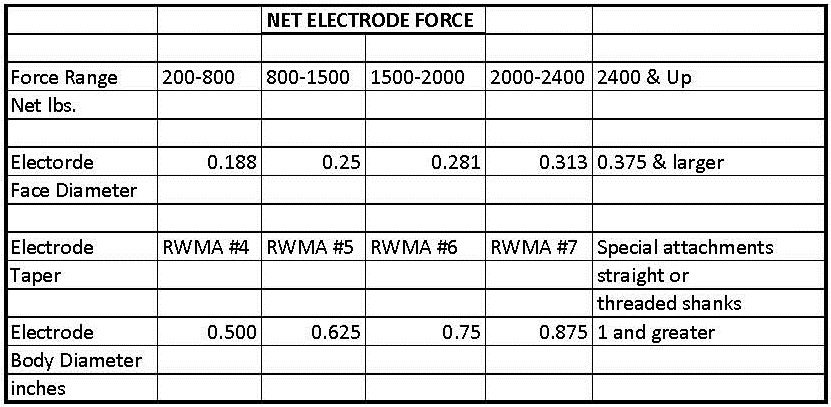

This chart indicates the proper taper/electrode size or thread vs force.

As the duty cycle or demand of the application goes up – force and heat. This my change and other attachments become better choices. The chart above shows that at 2400 pounds force tapered electrodes must be replaced with threaded or flanged electrode designs. Nut welding is a large user of threaded faced electrodes with locator pins. The forces, and heat make the tapered electrode not a good choice in many of heavy-duty nut weld applications. The threaded electrodes are easy to remove and refurbish and replace as desired. Tapered electrodes are used for nut welding but it comes down to how much heat and force they see. How often will the electrode need to be removed and how difficult will it be. If it only needs to be changed once a week that is great but if it won’t come out of the tooling ??? You have lost the entire fixture. Choose the tapered, threaded or flanged electrode system that can be removed with less difficulty.

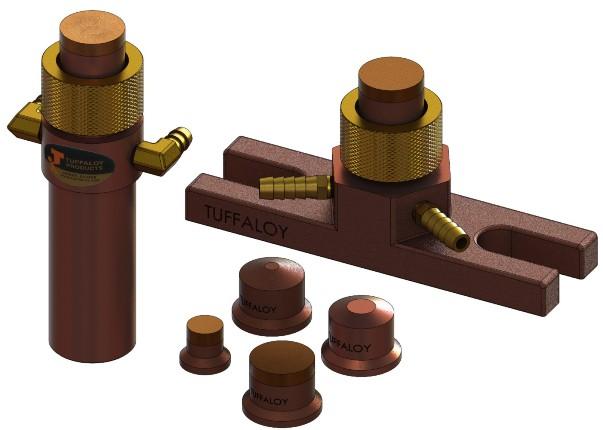

TAPERED NUT ELECTRODES THREADED WELD NUT FLANGED WELD SYTEM

All three systems can be alloy copper faced or copper/tungsten faced, with or without locator pins.

This discussion applies to more than nut welding. It can also apply to any projection welding if electrode wear and changing becomes an issue.

Contact your local welding distributor for advice in making the proper system choice.

Reference: RWMA Resistance Welding Manual 4th Edition

Tuffaloy Resistance Welding Products Catalog