Projection Welding

Questions and Answers

This question brings out a very interesting situation. There are several sources for projection welding schedules published, some in industrial standards and literature. Considering that nuts and bolt welding make up such a large percentage of projection welding it would seem that standards might be available. However, I am not aware of a standard for nut and bolt projection welding. Due to the multitude of nut and bolt designs the users and standards people have not been able to collect the necessary data to form a consensus and develop a standard for nut and bolt projection welding.

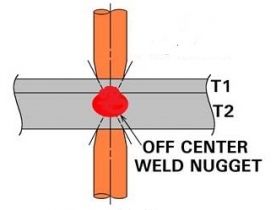

“X” theory can be referred to as heat balancing in spot welding where a 90 degree X drawn through the weld nugget at the faying surface and intersecting the surface can indicate the proper electrode face to move the nugget to the faying surface. In the drawing below the upper electrode would remain the same diameter and the lower would increase in diameter to move the nugget up if a 90 degree X were drawn.

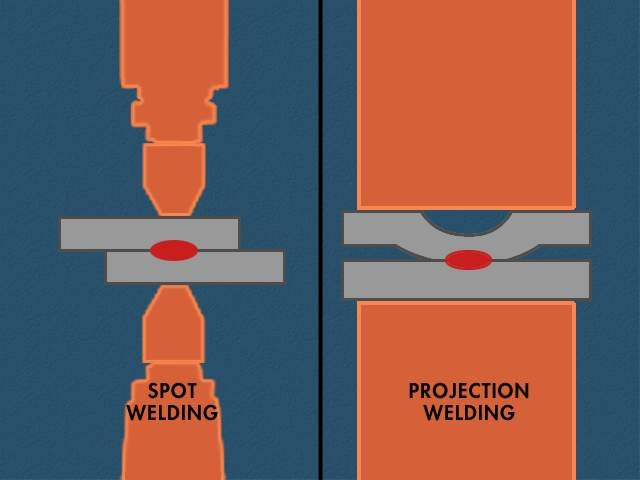

In projection welding heat balance and “X” theory are not necessary because the projection is designed to concentrate the heat where you need it, at the faying surface.

The electrode geometry and size is only necessary to deliver current and force to the part.

Normally flat electrodes with diameter larger than the work piece are used.

Alloy selection is generally Class 2 but if mechanical wear is an issue Class 3 may be used. In the case of nut welding where heat may be an issue Class 11 copper/tungsten frequently is an economical choice with a coated or ceramic locator pin.

The electrodes mainly capture and align all components for the welding operation. In the end they provide the force and current. Electrode size is generally not critical. Usually the electrode is larger than the nut, bolt or wire being welded.

In general projection welding is an easy job for the electrode since part design determines the weld nugget size, shape and concentrates the heat.

Reference:

RWMA Manual, Fourth Edition

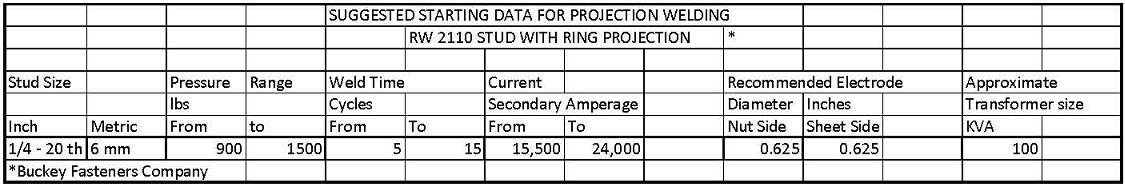

The RWMA Manual and AWS C1.1 and others do not offer any published weld schedules for projection welding ring projections. A manufacturer of studs does offer some input on the subject. The RW 2110 stud has a full ring projection on a ¼-20 (6mm) threaded bolt. The following information is available to use as a starting point:

The answer to this will be weld nut manufacturing methods, cost, and final product design requirements. Nuts are generally formed with three to six projections on the one side. More projections would be used for higher strength applications. The shape of these projections also varies from points to rounded with various heights. The material being welded may also dictate the projection style and weld schedule speed or need for tempering if working with high strength steels. Nut manufacturing cost and final desired nut welded strength determine which style will be best for your application. Pointed and round projections will both make good projection welds. The question is which style and how many projections will be the most consistent in size, shape and final welded strength for your application.

In projection welding the design or shape of the part is used to make discreet individual point or contacts to concentrate the current during the welding process. In some applications a full ring projection or part edge is used to form a complete seal. The TO-5 transistor can is an example of a hermetic sealed device. The full edge of the bottom comes in contact with the lid and a full hermetic ring weld is formed. The actual current flow is controlled by the part design. The electrode is there to deliver force and current into the two work pieces and provide follow up force as the weld is made. Frequently Class 2 & 3 electrodes are used. In nut welding applications Elkonite facing electrodes are commonly used on the sheet steel side. The use of dissimilar electrode materials in projection welding is common. Normally it is done to improve mechanical wear or to resist the heat being generated.

Page 11 of 14

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.