Projection Welding

Questions and Answers

Yes, projection welds like any spot weld if not performed properly have the potential to generate weld spatter or expulsion. The variables that must be controlled are alignment, projection size, shape or missing, force follow-up and weld schedule. Their variation may result in spatter if:

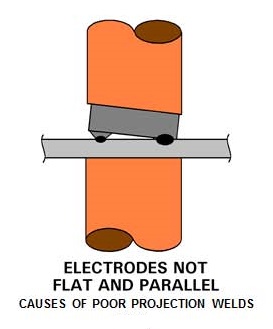

ALIGNMENT: If the pressure is not applied and the multiple projections do not make contact at the same time or with the same pressure, one or more will carry most of the current and overheat. This overheated projection or projections have the potential to expel material. The final projection when it makes contact will do so under current which means an arc will occur. An arc can always lead to expulsion.

PROJECTION SIZE OR SHAPE: When welding multiple projections, if the projections are not the same size, shape or missing there is a potential for inconsistent welding. When the projections make contact at the same time, but they are different sizes they can heat at different rates. One projection can overheat which could lead to expulsion. If size is dramatically different, one projection may not make initial contact. When the other projections begin to collapse due to carrying too much current the then the last projection will make contact with the current on and make an arc. Flash, expulsion or spatter could result from the arc or from the over heated original contacted projections.

FORCE FOLLOW-UP: It is imperative that as the projection begins to heat up and collapse that the weld head maintains force and full pressure on the projection as it collapses. This insures a good strong weld. If the weld head sticks or is slow the weld strength will suffer and the strength will be low or in an extreme case no weld and flash, expulsion or spatter could result.

WELD SCHEDULE: A proper weld schedule is always important to efficiently apply the proper force, bring the projections up to temperature and forge the weld with the proper fast follow up.

Projection welding parameters are readily available in published weld schedules referenced below. In general they have relatively short weld times and perform very well as documented. There are cases in which the circumstances in manufacturing are not ideal and variations from the standard are necessary. In these circumstances a change in the weld schedule may help.

As stated in another article “How Do I Dress a Resistance Welding Electrode”, the best way is to remove the electrode and remachine it in the tool room where it can be done accurately. For projection welding this may be the only option if the electrode has elaborate machined surfaces or dimensions. If the projection face is merely a flat face which many are other option are possible.

There are no specific tools that I would recommend for dressing.

Manually a block of wood with emery paper on one or both sides as needed. Close the electrodes with lite pressure and rotate the emery paper till the desired flatness is achieved. This could also be a two sided fine flat file followed by fine emery paper.

This question brings out a very interesting situation. There are several sources for projection welding schedules published, some in industrial standards and literature. Considering that nuts and bolt welding make up such a large percentage of projection welding it would seem that standards might be available. However, I am not aware of a standard for nut and bolt projection welding. Due to the multitude of nut and bolt designs the users and standards people have not been able to collect the necessary data to form a consensus and develop a standard for nut and bolt projection welding.

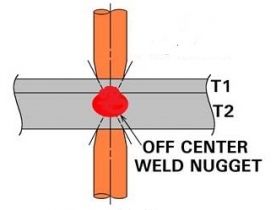

“X” theory can be referred to as heat balancing in spot welding where a 90 degree X drawn through the weld nugget at the faying surface and intersecting the surface can indicate the proper electrode face to move the nugget to the faying surface. In the drawing below the upper electrode would remain the same diameter and the lower would increase in diameter to move the nugget up if a 90 degree X were drawn.

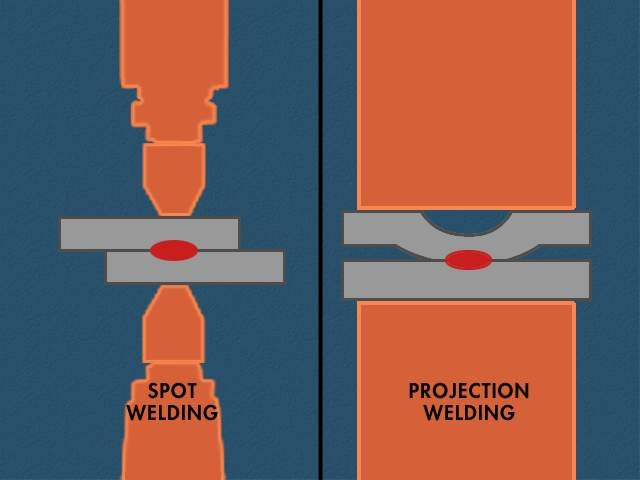

In projection welding heat balance and “X” theory are not necessary because the projection is designed to concentrate the heat where you need it, at the faying surface.

The electrode geometry and size is only necessary to deliver current and force to the part.

Normally flat electrodes with diameter larger than the work piece are used.

Alloy selection is generally Class 2 but if mechanical wear is an issue Class 3 may be used. In the case of nut welding where heat may be an issue Class 11 copper/tungsten frequently is an economical choice with a coated or ceramic locator pin.

The electrodes mainly capture and align all components for the welding operation. In the end they provide the force and current. Electrode size is generally not critical. Usually the electrode is larger than the nut, bolt or wire being welded.

In general projection welding is an easy job for the electrode since part design determines the weld nugget size, shape and concentrates the heat.

Reference:

RWMA Manual, Fourth Edition

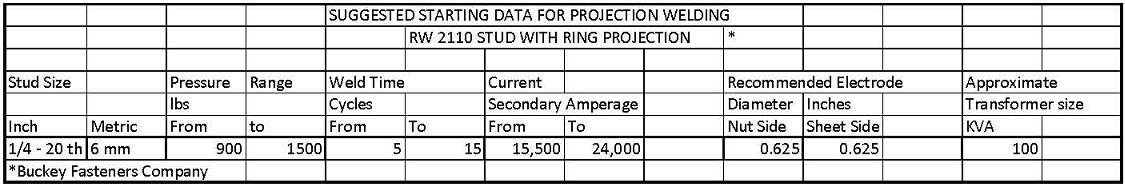

The RWMA Manual and AWS C1.1 and others do not offer any published weld schedules for projection welding ring projections. A manufacturer of studs does offer some input on the subject. The RW 2110 stud has a full ring projection on a ¼-20 (6mm) threaded bolt. The following information is available to use as a starting point:

Page 10 of 14

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.