Projection Welding

Questions and Answers

Material at 0.250” (6.4 mm) is generally beyond the limits for resistance spot welding. This question did not define the shape of this bar (round or square). The possibility of using a resistance welding process is viable on this bar with either shape if projection welding is used.

This question should be further elaborated to include how close should the fixture bottom support be to the outside of the nut wall? Secondly which is preferred a ball end shaped rod or a threaded bold for even consistent force application.

ASSORTED WELD NUTS

This is a question in two parts – Fixturing the assembly to be evaluated, and the push off tooling used to apply force directly against the actual weld nut.

Projection nut welding is an important process within the resistance welding community. Many different segments of industry use this process in the fabrication of their products. Automotive, appliance and aircraft are examples of a few.

ASSORTED WELD NUTS

Ironically, with millions of nuts being projection welded there is very little data published on the process. In another article in this blog:

"WHAT ARE THE QUALITY STANDARDS FOR NUT PROJECTION WELDING?"

The lack of data was addressed. Two published articles were referenced:

AWS WELDING JOURNAL: RWMA Q & A JANUARY & MARCH 2011 – “QUALITY OF FORGED PROJECTION WELD NUTS”

Ring projections can be a round radius faced annular ring on one face of the part. Frequently the ring is a “V” shaped ring on the face of the part. Be it a ring or individual projections the process is the same. The projection design concentrates the force and heat on the part and heat will generate there when current is applied. The connection on the top of a water heater is an example we are all familiar with. This annular projection prevents the connection from leaking water during use.

TYPICAL RING PROJECTIONS

To develop the process to make this type of weld, some starting information is helpful. There is not much available. THE WELDING INSTITUTE in the UK “TWI” does have some basic data available.

They offered some information on general design considerations. Most importantly they offered estimated values of force, time and current.

Cross wire welding is a form of projection welding. When two wires are crossed that is a point contact. The heat and force are concentrated at that point contact. Even welding a wire to a sheet is a projection weld concentrated in a line point contact. Weld schedules are available in the literature for this type of operation.

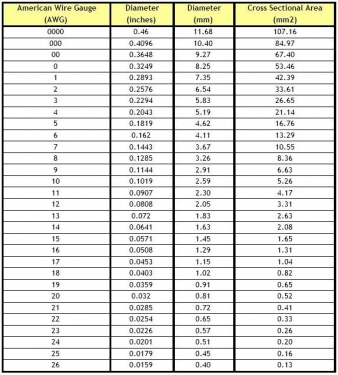

The American Wire Gage Chart:

Knowing the wire size one can look up a possible weld schedule in:

AWS Standard C1.1 Recommended Practices For Resistance Welding

Page 8 of 14

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.