Projection Welding

Questions and Answers

It is likely that a standard published 3 or 4 projection weld schedule does not exist in the literature. The options are start testing from scratch or look at spot welding data for the same material that may exist.

The best way is to use a known similar weld schedule to estimate for the initial test coupons.

Simply use the data for one spot weld and multiply current and force by three or four depending upon spot spacing. Time stays the same.

FOUR PROJECTION PART

Projection nut welding is done every day in sheet metal fabrication shops. In most, tooling is used to locate the nut on the part. A centering pin is frequently part of this tooling.

AUTOMATED NUT FEED TOOLING COMPONENTS

These pins function as a locator and in most cases also have to be an electrical insulator to prevent current flow through the pin and damage to the threads of the nut. To prevent this the locator pin is electrically insulated by some means.

The question posed above is: What material is best for nut welding? This applications demands good wear, long life and insulation. Options in the marketplace are:

Solid Ceramic pins

Metallic Pins (insulated by an insulating sleeve or coating in the holder)

Ceramic coated metallic pins

All three are being used. They all work. They all have pros and cons.

In automated systems the pin will see impact abuse as the parts are loaded. Each time the nut loads friction can cause wear on the ceramic surface or coating. Flash can cause the pins to stick and not retrack, increasing the abuse. The pins take a lot of abuse and see a lot of heat. We have: IMPACT, FRICTION, FLASH and HEAT. These problems lead to nut misfeeds or thread arcing and damage.

Which of these issues is present?

Which pin design is the best to solve that issue?

Is it cost effective?

Is it available in the quantity needed?

A material with a yes to all of these questions is the best material for the application.

A local distributor or supplier will be able to help in the evaluation of the best option for the application.

Reference: RWMA – Resistance Welding Manual 4th Edition

NPN and PNP are Bipolar junction transistors. They come in two configurations. PNP has a negative output and NPN has a positive output to industrial controls.

PNP TRANSISTOR

The 70% value in a resistance welding standard/specification is typically associated with the projection welding of coined/forged/solid weld nuts. For context, the embossed/stamped projection welding requirements detailed in both the RWMA Manual, and the AWS C1.1, only state what sort of weld strength is required, not the required weld size.

Over time individual manufacturers performing projection welding developed standards based on nugget size as an alternative to pulling tensile tests. To be more specific, the 70% value is typically applied to the size of the weld in relation to the projection when subjecting the part to destructive evaluation. For the record, some standards use a value of 80%.

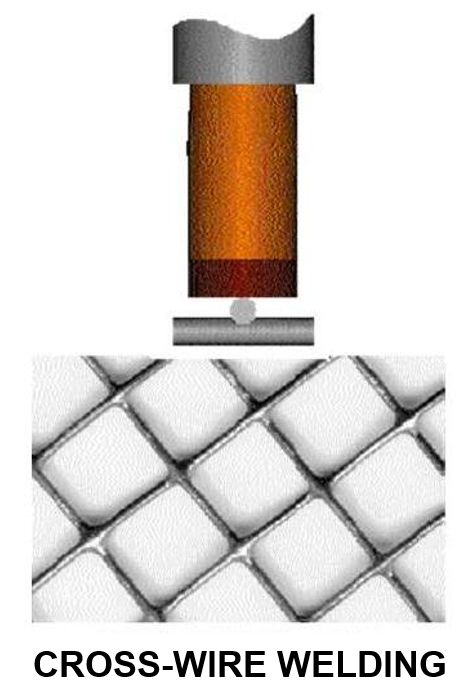

One cannot calculate the welding parameters (squeeze, weld, hold – force & amperage). A very similar question was recently answered for 4MM wire.

CAN THE BUTT END OF A 4MM (0.156”) MILD STEEL WIRE BE PROJECTION WELDED AT 90 DEGRESS TO A PIECE OF 4MM (0.156”) MILD STEEL WIRE?

The process is very doable but the parameters are likely not published. They cannot be calculated. One will need to either consult the literature for similar operational data or do trial and error.

Another article in this blog describes the steps one must follow to do the trial and error:

“HOW DO YOU DEVELOP A PROJECTION WELDING PROCESS?”

This outlines the processes to develop a schedule and the important factors to consider in setting up the equipment:

FORCE APPLICATION AND FOLLOW-UP

ALIGNMENT

PROJECTION SHAPE, SIZE & CONSISTENCY

ELECTRODE MATERIAL AND CONFIGURATION

A “T” weld is not a cross wire weld. It is a projection weld similar to an elongated projection weld. The most important factor will be the cut off of the wire end. Secondly, fixturing it to maintain its perpendicularity as force is applied. Good tooling and maintenance can make this work and many good welds will be produced.

Reference: AWS C1.1 Recommended Practices for Resistance Welding

AWS J1.3 Specification for Materials Used In Resistance Welding Electrodes and Tooling

AWS J1.2 Guide to Installation and Maintenance of Resistance Welding Machines

Page 6 of 14

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.