As described in another article:

Constant current is a very useful feature of today’s controls. If this feature is present and you ask for 10,000 amps. The control will deliver that amperage each weld. It won’t matter if you are near the edge of the part or half way across the part. The resistance caused by the impedance is corrected by the constant current. Every weld will receive the same desired current. If you are projection welding one part in the same position each time impedance is not an issue. Knowing that you always get the proper current is a very good feature under most situations.

Another plant variation is line voltage. See the article:

During the day as equipment comes on and off line it can cause the plant supply line voltage to vary. This will create a problem for the control to deliver the proper current output. A constant voltage control corrects for this and will maintain the desired current output. Without this feature the weld current will vary and the projection welds may vary.

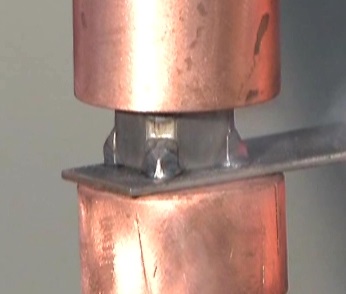

PROJECTION NUT WELD

Refeerence: RWMA Resistance welding Manual 4th Edition

REFERENCES: RWMA - Resistance Welding Manusl 4th Edition