Controls & Transformers

Questions and Answers

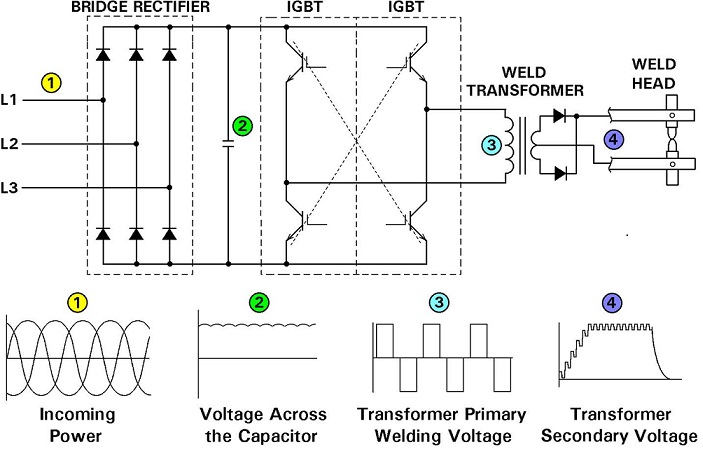

MFDC stands for MID FREQUENCY DIRECT CURRENT. Three phase AC @ 60 hertz input is converted to a high frequency 400-4000 Hz input to the transformer. The transformer then produces a DC output to the welder.

SCHEMATIC AND POWER CONVERSION IN CONTROL AND TRANSFORMER OF MID FREQUENCY INVERTER

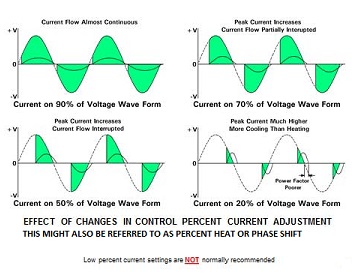

AC stands for alternating current. Historically in North America the standard welding controls have been single phase AC @ 60 Hz input. The transformer produces a low voltage high amperage AC output at 60 Hz suitable to produce the desired welding parameters. The Typical AC sine wave outputs would look like those shown below.

Each time the sine wave crosses zero the AC weld actually cools momentarily. Additional cooling occurs depending upon the amount of phase shift as shown above. As the heating accumulates the part heats up. AC equipment is very robust and can last a lifetime if properly cooled and operated within its rated capability.

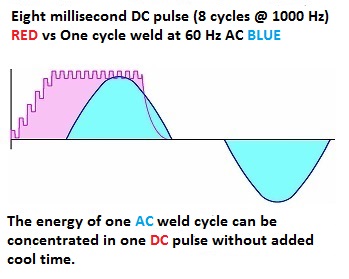

MFDC is timed in milliseconds (ms). There are 16 ms in one 60 Hz AC sine wave. Because MFDC heats continuously, DC actually can produce the same amount of heat of one AC sine wave in much less time as demonstrated below:

This attribute of heating without a zero cross over and no phase shift allows MFDC to heat quickly. Another feature is that inductive losses are nearly eliminated with DC. Therefor MFDC transformers can heat the parts with less power. Additionally MFDC transformers are operated at higher frequency’s which allows them to be made smaller. Smaller means less weight for a robot arm to carry.

MFDC has become the system of choice in the automation world. Timing in (ms) allows finer control of the process which can result in better process results.

Many applications are turning to MFDC because the process can:

Lower weight

It is fast

Reduce power requirements

Better resolution of heat control

The water itself would have some conductive properties but they should be very low as specified by AWS J1.2:2016. The machine, transformer and control should all be grounded. Therefore, the water does have a potential path to ground.

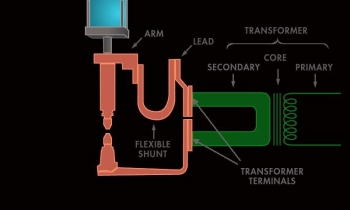

WELDER SCHEMATIC WITH COPPER CONDUCTORS

In the resistance welding process the secondary voltage is low, frequently 4-6 volts. With this low voltage the current is going to flow through the most conductive path. This is the copper and copper alloy conductors present in the form of conductors, shunts, cables and electrodes. The water potentially can conduct but is highly resistive relative to the copper conductors and very little conduction will be present. The water conduction will be minutely small in comparison to the thousands of amperes conducted through the copper system. This minimal flow pattern in the water is the same in AC or DC systems.

Reference: AWS J1.2M:2016, Section 4.5

Resistance Welding Manual, 4th Edition

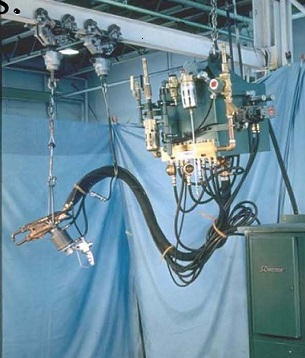

A portable resistance welding gun was used frequently in the past but has seen less use with the introduction of the robot transgun. The portable gun is suspended from an overhead trolley by cables which carry most of the weight. The gun consists of the electrodes and force system. The portable gun transformer is located generally overhead and the power is transmitted by kickless cables (low impedance/water cooled) to the gun. These systems are still in use for respot/rework, remote robot and manual guns.

PORTABLE GUN & TRANSFORMER

PORTABLE GUN TRANSFORMER

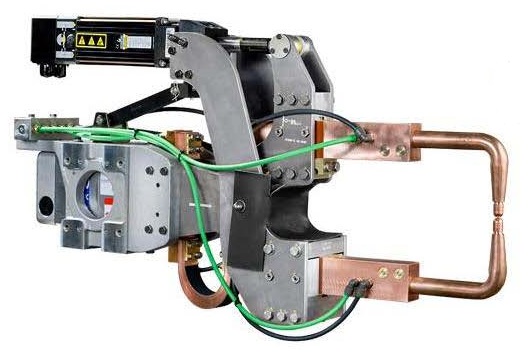

Transgun AC transformers are designed to be relatively light and compact with good power to fit on a robot arm for welding applications. These transformers vary in sizes from 35 KVA to 136 kva units (rated at 50% duty cycle). They are lightweight and designed for close couple mounting to welding guns. Their light weight makes them ideal for robotic applications.

TRANSGUN TRANSFORMER

For many years AC was the system of choice for resistance welding. DC was present for those applications that demanded high power where balanced three phase input and large secondary outputs were necessary.

Over the last twenty years MFDC (mid frequency direct current) offered a means to lighten the weight of the transformer which made robotic welding a practical resistance welding application.

Transgun with MFDC Transformer and Servo Actuator

Today MFDC is the largest application of resistance welding transformers. It has found wide acceptance in all industries. It is a balanced three phase, can use less power and has a power factor near unity.

The power factor comparison is:

AC – 0.3-0.8 (Varies with throat configuration)

MFDC- 0.99

Reference: Roman Manufacturing - White Paper 2017 “A Comparison of AC to Inverter DC Resistance Spot Welding and the Effects On Dual-Phase 600”

Page 15 of 40

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.