Controls & Transformers

Questions and Answers

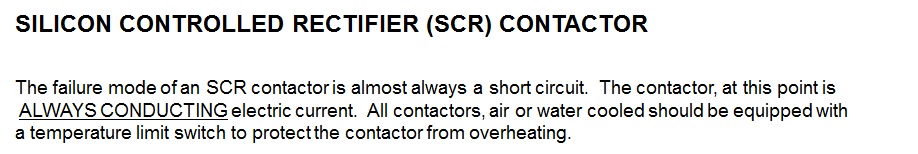

The SCR contactor is a component of the AC resistance welding control. The control initiates the time and frequency of the SCR’s activation and passing of current. This current of course goes to the transformer primary and is converted to low voltage high current in the secondary of the transformer to travel to the electrodes and make the spot weld. The SCR is the on off switch for this process. It functions on every half cycle of current as instructed by the control.

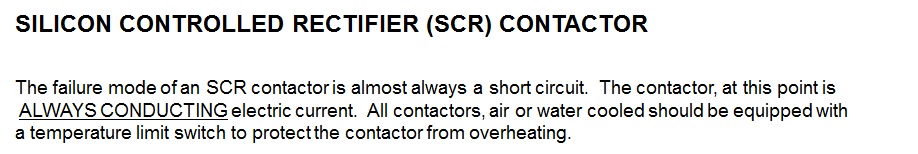

The SCR contactor is a solid state device with no moving parts. It is very fast and reliable. As with all electronics it is sensitive to heat and must be cooled by air or water depending upon its service rating. A temperature limit switch is recommended.

If one of the two SCR’s has failed as noted above, it usually fails in the on mode, The transformer will be under full power. The control will not see this. If activated the electrodes will get VERY HOT. The circuit breaker may trip?

Test voltage across the electrodes when open if they have voltage the SCR has failed.

Sometimes SCR’s don’t short out and trip the breaker. Occasionally they fire erratically. If only one SCR fires, this is called half cycling. The transformer is out of balance and will make a grunting sound, vibrate, current will spike and the breaker may trip.

Generally, a failed SCR leads to voltage when there should not be any at the electrode. The second less frequent events are strange erratic happenings, sounds and tripped breakers. If you are not sure what you are dealing with make a call to your local equipment supplier or distributor who likely has dealt with this situation before.

Reference: RWMA Resistance Welding Manual 4th Edition

The SCR contactor is a component of the resistance welding control. The control initiates the time and frequency of the SCR’s activation and passing of current. This current of course goes to the transformer primary and is converted to low voltage high current in the secondary of the transformer to travel to the electrodes and make the spot weld. The SCR is the on off switch for this process. It functions on every half cycle of current as instructed by the control.

The SCR contactor is a solid state device with no moving parts. It is very fast and reliable. As with all electronics it is sensitive to heat and must be cooled by air or water depending upon its service rating. A temperature limit switch is recommended.

If one of the two SCR’s has failed the transformer will be under full power. The control will not see this. If activated the electrodes will get VERY HOT. The circuit breaker may trip?

Test voltage across the electrodes when open if they have voltage the SCR has failed.

Sometimes SCR’s don’t short out. Occasionally they fire erratically. If only one SCR fires, this is called half cycling. The transformer is out of balance and will make a grunting sound, vibrate, current will spike and the breaker may trip.

Generally, a failed SCR leads to voltage when there should not be any at the electrode. The second less frequent events are strange erratic happenings, sounds and tripped breakers.

If you are not sure what you are dealing with make a call to your local equipment supplier or distributor who likely has dealt with this situation before.

Reference: RWMA Resistance Welding Manual 4th Edition

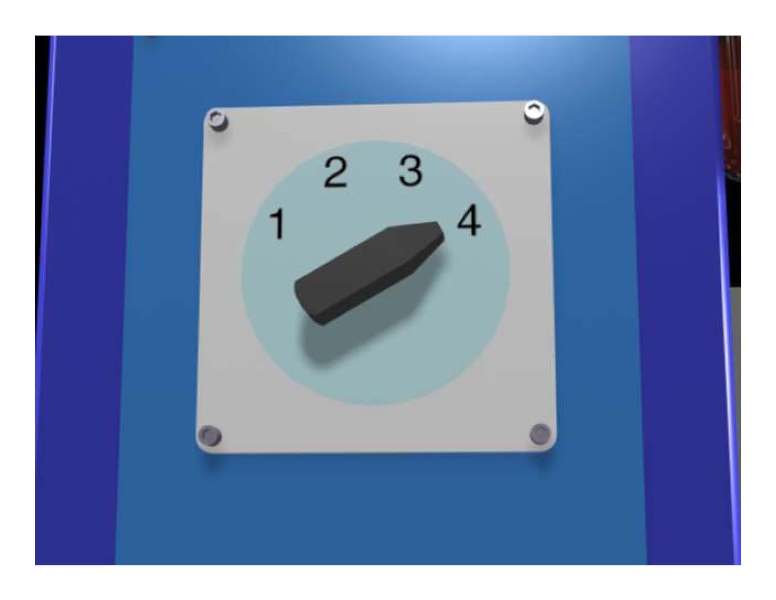

The transformer tap switch of a resistance welding transformer is installed on the windings of the primary side of the transformer. By changing the tap switch one is changing the turns ratio of the transformer. When the turns ratio changes it will change the voltage in the secondary coil. Tap 1 will produce the lowest secondary voltage and the highest tap will produce the highest secondary voltage and potentially the maximum KVA rating of the transformer.

See article:

DO I NEED TO INSTALL A SERIES BAR TO MEASURE THE TURNS RATIO OF A RESISTANCE WELDING TRANSFORMER?

PRESS WELDER TAP SWITCH

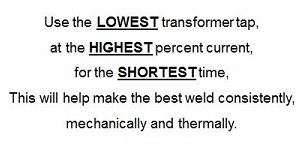

As a suggestion to get the best performance:

To see other articles on this subject do a search on transformer taps in this blog.

References: RWMA – Resistance Welding Manual 4th Edition

This answer to this question is included in the answer of another article:

HOW DO YOU SIZE THE PRIMARY CONDUCTORS FOR AN AC RESISTANCE WELDING TRANSFORMER?

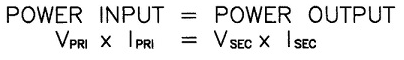

It builds upon the formula:

In this instance we have a 250 KVA AC machine transformer with a high tap of 25.8 volts and a low tap of 12.9 volts.

All of this depends upon not overheating the transformer Therefore we must operate at no more than 50% duty cycle. The above article explains how to insure the transformer is operated under safe conditions:

If the Duty Cycle or Weld Current are not known or this is a general purpose machine:

1. Divide the transformer nameplate KVA by the primary voltage.

2. Multiply that result by the square root of 0.5 (RWMA transformers normally are rated at 50% Duty Cycle)

3. The result is the Primary Effective Continuous Thermal Current (ECTC).

4. Refer to the Ampacity Chart of the cable type to be used. Select the size based on the Primary Effective Continuous Thermal Current (ECTC).

Ampacity charts are based on the National Electric Code (NEC). There may be other state, local or company standards that must be followed.

Reference: National Electric Code

RWMA Manual Chapter -21.7

Roman Manufacturing Inc.

Wire is used in some non-resistance welding transformer applications. The design of transformers used in resistance welding can be very demanding and must be designed and built accordingly. This blog does not get involved with machine design and build subjects. Contact your local machine sources or distributors for information and assistance.

Reference: RWMA Resistance Welding Manual 4th Edition

Page 6 of 40

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.