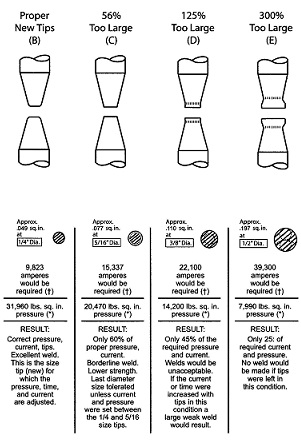

It is not a perfect world but in a perfect world one wants to maintain a constant current density at the electrode face. Therefor as the electrode face grows, the current should be increased to match this growth. A simple chart demonstrates this and is published in many places. Here is an excerpt:

This Figure demonstrates the growth of the weld face and the need to increase the weld current at a rate to maintain the original current density.

The diameter increase from ¼ inch (6.35 mm) to 3/8 inch (9.53 mm) is a face area increase from 0.049 in2 to 0.110 in2. This is a 125% increase, more than double the surface area. To maintain the current density the current has to increase a similar amount from roughly 9,800 to 22,000 amps. Remember that surface area changes based on diameter squared not the change in diameter. That explains the large increase.

Since it is not a perfect world, there are differences in materials, coatings, material thicknesses, conductivities, weld spacings, tooling and many other factors. An exact adherence to this ratio probably won’t hold but it certainly is a place to start.

Current can be adjusted with automatic steppers, manually or not at all, depending upon the operating environment. To maintain good product something must be done before the weld nugget fails. The electrode will mushroom with time.

Reference: CMW Inc.: Welding Products Catalog, 2018

RWMA: Resistance Welding Manual 4th Edition