This question was generated after the person read the article in this blog:

“IS THERE A MINIMUM SPACING BETWEEN SPOT WELDS”

SPACING:

If we compare the two processes. A spot weld is a point weld. Generally, an arc weld is a line.

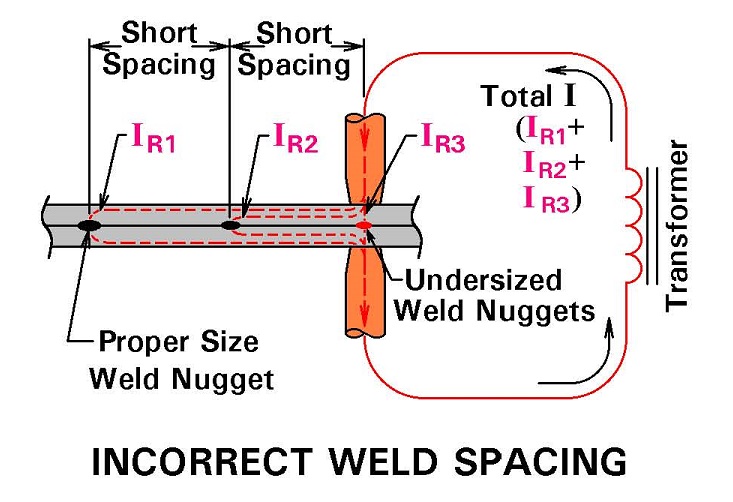

Number of spot welds and spacing is determined on an individually based on material composition, thickness and desired specification of the welded components. Shunting can and will occur but with little impact if the spacing recommended in normal standards are followed.

Location and number of Arc weld beads is similarly determined as to location and length of beads based on structural requirements and material being welded. Spacing of arc beads is probably greater than individual spots.

Process:

The second area that might be of concern is processing. If the product is to be spot welded do so before arc welding. SMAW and GMAW welding sometimes generate surface conditions that make it very difficult for a resistance welding electrodes to conduct through.

Reference: RWMA – Resistance Welding Manual 4th Edition