Spot Welding

Questions and Answers

Another variation of the series weld is the push-pull weld. In this process the electrodes are connected to separate secondary circuits on both sides of the weldment. The polarities are arranged as shown for proper current flow. Shunting current is still present but now in both workpieces. The voltage between the electrodes increases the weld current to shunting current ratio when compared to other series weld set ups. Therefore you get more power delivered to the weld.

In a series weld the current is conducted into the part by two electrodes touching the part from the same side. A weld is produced at each electrode. One electrode serves as the positive the other as the negative. The current flows into the part and through the desired weld joint and through the part and or backup mandrel to the second electrode. It makes a second weld at the second electrode. This type of set up frequently allows for all electrical components to be designed to be on one side of the part.

A direct weld is a standard spot weld where the current path is directly through the workpiece between opposing electrodes. This is the easiest weld to produce. The electrodes size and face shape can be optimized for the application. The face can be radius or flat to produce the desired spot weld.

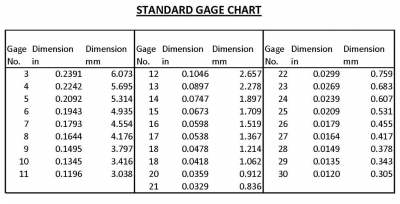

On many specifications the material call-out is a gage number. If you are not familiar with this term you cannot go forward with a weld schedule. You must know the material thickness which is what the gage number represents. Below is a table showing the gage size standard for steel sheetmetal.

Reference: Tuffaloy Catalog 2017

A resistance braze offers a few advantages over traditional spot welding:

First it allows the joining of materials that otherwise cannot be resistance welded. Generally they are very conductive materials and hard to get hot enough to form a weld nugget. Coppers and brasses would be an example of these.

Secondly a resistance braze can be performed at a lower temperature than a spot weld. We do not have to bring the work piece up to near its melting point. We only need to bring the braze shim to its melting point which is much lower. This means the work piece can preserve some or all of its mechanical properties. Post heat treatment may not be necessary.

The third advantage is that we can control the area of heat application to a small area of the part. We are only heating to a modest temperature and we can protect other areas if desired with cooling. The rest of the part stays strong for the end application.

Reference: CMW Products Inc. Catalog

Tuffaloy Products Catalog

RWMA, Resistance Welding Manual. Section 1, Chapter 6

Page 33 of 44

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.