Seam Welding

Questions and Answers

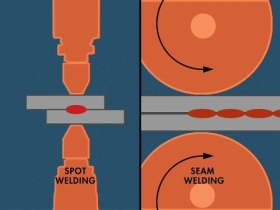

Seam and spot weld are similar in many ways. They both make individual welds with the same basic process of squeeze, weld and hold. The heating principal is the same “Ohm’s Law” H = I2 rt. The electrodes are different. One employs a wheel the other a single point electrode. Their weld faces are a little different but still act to concentrate the current and force into a point contact on the part. In simple terms they produce the same individual welds.

Seam welds generally are closer together and frequently produce fluid tight seals. Spot welds normally are not that close together and are not water tight. Testing is performed on seam and spot welds in similar fashion by destructive testing of coupons or product in most shops.

Seam welding wheels are driven and move the work piece. Spot welds electrodes are stationary and the product comes to it or robots move the weld electrodes to the weld locations.

Reference: RWMA – Resistance Welding Manual Section 4

A lap seam weld is when two work pieces are slightly overlapped along their edges. Then this overlapping area is continuously seam welded. The overlapped metal is mashed down and welded at the same time. They overlapped slightly so this is not a butt joint. It is usually a continuous fluid tight joint. There will remain some raised metal at the joint.

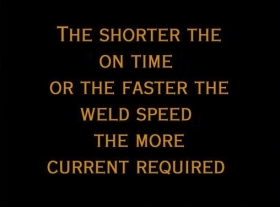

Seam welding especially in a continuous mode can be a major power consumer. It can really be surprising the first time you see a drum or dishwasher water tight weld being welded. It may look and sound like the machine is welding continuously. It is not. Seem Welders never exceed 50% duty cycle. The equipment is designed for a maximum 50% duty cycle. If run higher they will fail prematurely. Therefor you may not hear it but half of the time the welder could be off as it is running. The closer the welds are together and the faster the wheels turn the more power will be consumed. A simple guide to power consumption is:

Reference: RWMA - Resistance Welding Manual 4th Edition

Inverters and DC controls with their DC output have small inductive losses. This gives them an advantage in total power consumption and they generally can run faster than AC equipment. It is a very good system for seam welding when high energy requirements are necessary.

Reference: RWMA – Resistance Welding Manual Section 4

When making a continuous seam welds sometimes warpage becomes an issue. A lot of welds and heat are going into the material and distortion can be created. The best method is flood cooling. Another method that is sometimes practical is to weld a modest length. Then skip a similar length. Weld another length and skip another length. Repeat till you reach the end then go back and pick up the skipped welds. This has proven successful in some applications. The best method to reduce warpage is flood cooling.

Page 9 of 11

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.