When a job is set up properly and the electrodes and water cooling are maintained it is still possible to have weld variation during a production day. It is very common that the line voltage at most production plants can vary during the day because of the demand on the Utility Company. The problem could be your feed to your plant or the Utility Company's main grid. It also could be overloaded power buses within the facility.

At the very start of a shift voltage may be fine but as the shift goes on more and more machines come on line and may exceed the demand and cause a drop in voltage. If this happens your welding conditions can be affected. The weld nugget could reduce and compensation may be necessary. Later in the day the utility demand might reduce because machines are dropping off line and the Utility Company can keep up and now voltage is back to normal and your original settings are good again. This means third shift might never see the voltage drops that first or second shift might see.

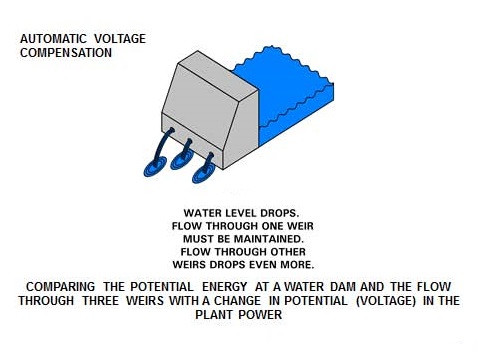

In today’s modern controls voltage compensation and constant current is available and can be used to correct for this condition up to a point. The second less desirable fix is to adjust the weld schedule manually to compensate.

Voltage/flow compensation is maintained at one weir while the others continue see reduced voltage/flow. Eventually there must be more power to cover the shortage being experienced.

Of course there are many other factors that must be watched for such as:

- electrode wear

- poor cooling

- loose connections

- overheating

- water temperature variations

- air pressure variations

- cylinder wear and conductor wear

Reference: RWMA - Resistacne Welding Manual 4th Edition