Pressure is one of the major components of the welding process Pressure, Current & Time (PCT). In most weld schedules pressure is called out as a force value. Pressure is this same value as force but applied to the surface area of the electrode contact face.

Pressure is important because it provides the necessary mechanical force holding the two or more surfaces together during the welding sequence. This insures a good current path and contains the molten metal that may form to prevent expulsion.

The term “Pressure-Controlled Resistance Welding” is not familiar to me.

Pressure is only one component of the process PCT.

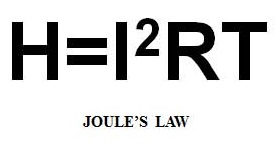

As shown current is the most influential factor in the process.

That stated. Without pressure the process cannot function. In many processes pressure switches or monitors are installed to signal the control or PLC. They signal the proper pressure has been reached during the initial pressure/force application for weld current to begin. This insures current does not initiate when the parts and electrodes are not fully engaged. If the proper force is not applied before the weld sequence, part expulsion and electrode damage is likely.

In this day of servo guns someone may call this pressure-controlled welding. It is not. It is merely insuring proper initiation.

Additional articles in this blog that address related pressure/force topics are:

What is the force component of a weld schedule?

How are force and pressure related?

What happens if I change the force?

Reference: RWMA – Resistance Welding Manual 4th Edition