A weld schedule is an instruction to set up a resistance welder for a given job. It includes all of the specific settings of the machine, control settings, tools, electrodes, forces, times, rates and all other pertinent data related to a job. It also includes the information about the part, including material, thickness, number of welds, weld locations, quality requirements, and precleaning. This information is stored and can be used to set up the job on it’s next run. It also can be used as a ground zero if parameters have changed and you want to go back to when the job started.

For initial set up general schedules are available for most materials. These schedules can be used as starting points to get going until you develop the exact settings for your machine and part. Schedules can be found in the AWS Standard C1.1 and the RWMA Resistance Welding Manual.

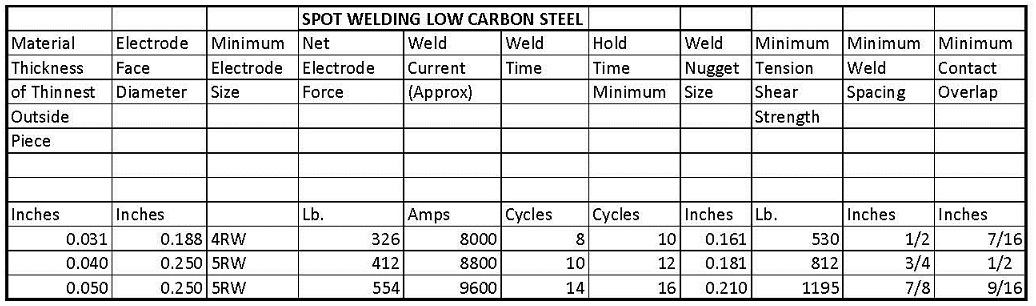

Below is an excert from the CMW Inc Resistance Welding Catalog showing weld schedule data for low carbon steel.

Looking at the 0.050” line of this typical schedule - This line tells you the specifications to set up for welding low carbon 1010 steel 0.050” thick on the thinnest outside sheet.

The data reads as follows:

#5 RW Electrode with a ¼” diameter face, alternate electrode #5 RW electrode with a 3” dome radius The notes tell you this is Class 2 electrode material

554 lb force

14 cycles of weld time

16 cycles of hold time minimum

9600 amperes current approximately

Resultant weld should have a shear strength of 1195 lbs

Weld Nugget of 0.210”

Minimum weld spacing should be 7/8 of an inch to prevent current shunting

Most published weld schedules read similar to this and are a good starting point. The actual schedule you develop will vary from this due to differences in materials being welded, machine variations, set ups and quality standards.

Always start initial welds at a current substantialy lower than the above in order to be cautious and prevent possible expulsion. After the first trial weld one can then safely adjust the current slowly up until heat and a weld are obtained.

Reference: CMW - Resistance Welding Products Catalog

Tuffaloy - Resistance Welding Products Catalog

AWS Standard C1.1, Recommended Practices for Resistance Welding

RWMA - Resistance Welding Manual 4th Edition