Weld controls like most other components on a resistance welder conduct large amounts of current. This current can generate heat. This heat must be dissipated for the equipment to operate efficiently. Yes, weld controls must be cooled. Lower amperage units can be air cooled. Higher rated units are water cooled.

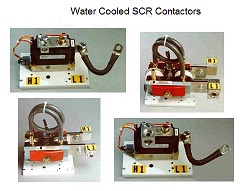

Here are examples of cooled SCR contactors used in weld controls. If overheated, the SCR’s can fail. They fail in the shorted - on mode. This is not good. Thus a circuit breaker is part of the standard equipment of a weld control and the unit is always grounded for safety.

Reference: RWMA - Resistance Welding Manual 4th Edition

AWS Standard - Guide to Installation and Maintenance of Resistance Welding Machines