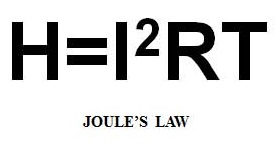

Controls in the marketplace control percent heat. Others control current. Many offer the option of controlling heat or current. Constant current is a common option on many current based controls. The question posed is should we base a weld schedule and ongoing process control on percent heat or current. The answer is simple. Joules Law shows us that current is the most important factor.

In the formula (I)current is squared. It has the most affect upon the heat.

Therefor we should monitor and control this factor CURRENT throughout the process.

Now let us examine three basic control types:

Percent Heat Controls

Percent Heat / Current read out Controls

Percent Heat/ Constant Current Controls

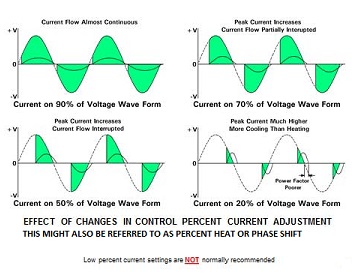

Percent Heat

This type of control allows one to select the percent of the sine wave to conduct current and heat the part.

Normally one prefers to operate at 50-70 % heat to reduce the cooling effects. Percent heat control is often used for welds lasting less than 3 – 5 cycles. Projection welds might be an example.

Percent Heat / Current Read Out Control

This is a percent heat control which has a current reading feedback for information purposes only. It would be used as the Percent Heat unit described above.

Percent Heat / Constant Current Control

This unit can be operated in percent heat mode as above or in constant current mode. In constant current mode the control will always produce the desired current at the weld every time. This is very important if multiple welds are made on ferrous materials with varying amounts of metal in the throat. The control will compensate for the impedance automatically. The control will also compensate for facility power fluctuations. Additionally if shunts and conductors wear constant current control can compensate.

In the case of short weld times less than 3 – 5 cycles it may not be as accurate as percent heat control. It takes 3 - 5 cycles for some constant current controls to establish the desired amperage The weld may be over by then.

Constant current is not a cure all. Machine & facility maintenance is still required.

The answer to the above question may be percent heat control with constant current. Use it properly and maintain all records on the weld schedule including both:

% Heat & Current

Reference: RWMA – Resistance Welding Manual 4th Edition

AWS J1.2 – Guide to Installation and Maintenance of Resistance Welding Machines