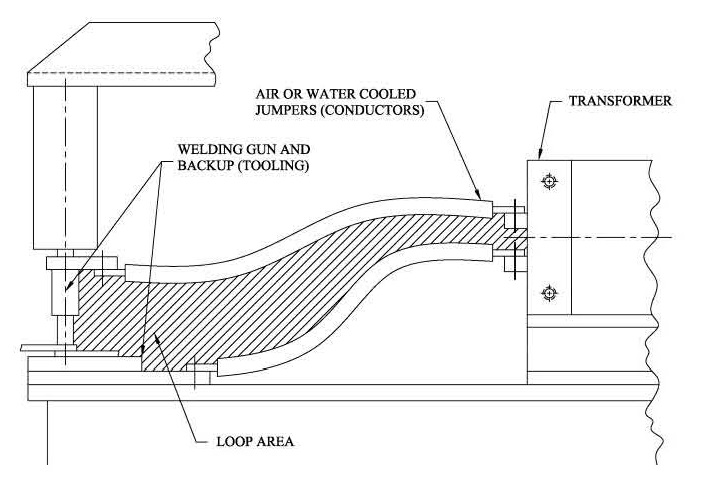

Throat size refers to the area of the welder enclosed by the path of the current from the transformer, through the conductors, electrodes then conductors and back to the transformer. A schematic is shown below. A robotic transgun and press welder all have a throat area. They are just different sizes depending upon the part being welded.

THROAT AREA

Size is determined by the job requirements. For power efficiency one should generally not size the throat area larger than required for clearance of the product. This is especially true for AC equipment where inductance and impedance are a factor. Large throat areas can dictate increased large transformer and control (power supply packages). This is dictated by the impedance losses. A job shop may weld many different parts on the same machine. This will dictate a larger power supply.

The science behind this is: “OHM’s LAW”

DC/MFDC does not have the same losses as AC but throat sizes are still minimized to minimize the magnet field area.

To optimize current flow minimize throat size and keep cables and conductors close together.

For more information read the articles in this blog:

What is Impedance in Resistance Welding

What is Reactance in Resistance Welding

Reference: RWMA Resistance Welding Manual Revised 4th Ed Chapter 19