Controls & Transformers

Questions and Answers

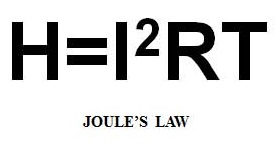

In resistance welding the heat is generated according to Joules Law:

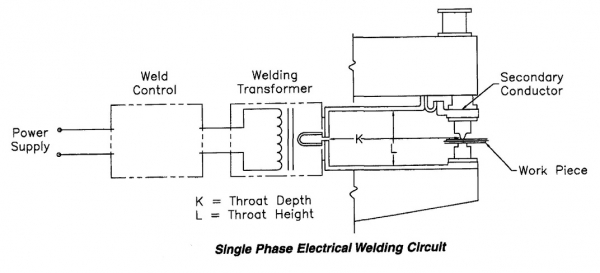

This dictates that relatively large currents will be passed through the weld joint to form the weld nugget. In order to do this economically and safely a transformer is used. The transformer’s function is to take a high voltage low amperage input and convert it into personnel safe low voltage high amperage output. The high amperage output is used to generate the heat defined in Joules Law.

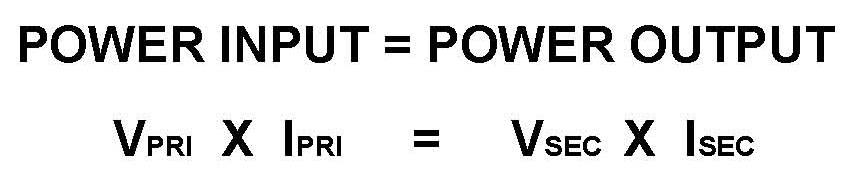

After the math is worked out:

Primary voltage times the primary amperage will equal the secondary voltage times the secondary amperage.

Through this system the power company is able to economically deliver the high voltage/low amperage power for conversion by the transformer to low voltage/high amperage welding power.

The secondary reason to reduce the voltage is to make it safe for people to be around. The secondary voltage of the transformer generally runs from 2 – 25 volts. This is safe for personnel to be around in the secondary. Proper grounding of all machines is still required. The control has high voltage inside and should be restricted to authorized personnel.

It is the transformer that enables us to deliver safe high energy power to the resistance welder to make resistance welds.

Reference: RWMA Manual Chapter 19

AWS J1.2:2016

Roman Manufacturing Inc.

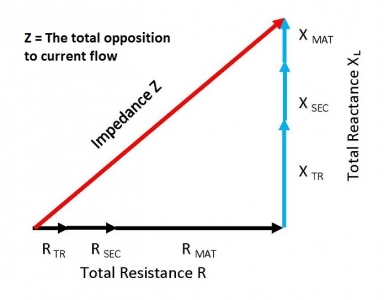

Impedance (Z) is the total opposition to current flow. It is made up of the Resistance (R) and Reactance (X).

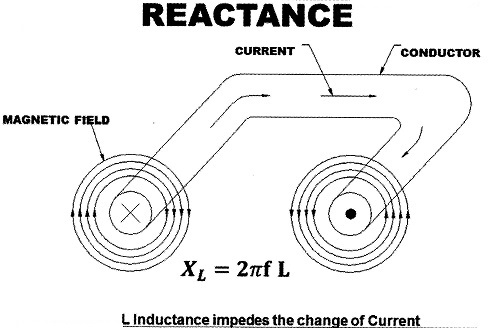

Reactance is created by the induced magnetic field around the conductors.

This induced field wants to stay in a steady state but in AC, current is constantly changing from positive to negative with the AC sine wave. The Reactance builds momentum in each half cycle and resists changing to the other direction. The stronger the magnetic field the larger the reactance (resistance). The size of the welder throat is a factor in determining this magnetic strength. Larger throat areas create stronger magnetic fields.

Ohm’s Law defines current as:

I= E/R

Where I is the current in Amperes, E is the potential in Volts and R is the resistance in Ohms.

In alternating current this formula becomes

I= E/Z

Where Z is impedance measured in Ohms.

(Z) Impedance has two components. They are R (resistance) and X (reactance).

The reactance of the secondary AC circuit is subject to changes in throat welder size and proximity of any magnetic materials. Therefore welder throat size is a factor in welder performance.

Larger throat sizes (K or L) increases the reactance and therefore the impedance increases. By Ohm’ Law the current will decrease with larger throat sizes.

The answer is two more coil turns in the primary of the transformer with the 47 vs the 45. This is not a lot of difference. Let’s discuss what turns ratio is. Turns ratio refers to the number of times the copper primary is coiled around the steel core in an AC transformer. For more information go to the article:

“WHAT IS TRANSFORMER TURNS RATIO?”

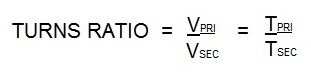

In it the following formula is given:

Vpri = Voltage on the primary Tpri = Turns in the primary coil

Vsec= Voltage on the secondary Tsec = Turns in the secondary coil

An AC secondary coil has one turn. So for easy math using 220 V input. The above formula results in:

The 47 turns would produce 4.7 V.

The 45 turns would produce 4.9 V

This is the voltage in the secondary circuit of the transformer. By changing the turns ratio we were able to change the voltage output of the transformer. Some transformers have tap switches built in. These tap leads connect to various points in the primary coil. This allows you to change the turns ratio of a transformer which gives you a multitude of voltages from one transformer.

See Article: WHAT IS THE LOWEST TRANSFORMER TAP?

Reference: RWMA Manual Chapter 19

Page 19 of 40

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.