Controls & Transformers

Questions and Answers

If there is 112 V present on the frame, between operations when the machine is in a sense idle. The first thought would be improper grounding. On an AC welder one pad of the transformer (usually the negative) is tied to ground. This could be the machine frame, which should be tied to the ground of the weld control, which should be tied to the ground of the supply feeding the machine. The input feed will include L1, L2 and a ground conductor. The ground from the input conductor should be tied to the common ground point that is bonded to the machine frame, AC transformer pad and weld control ground.

In some circumstances a floating ground or ground loop may be present and can cause an issue. Ground loops can be introduced by multiple ground paths. If this is the case and the issue cannot be resolved then a “Ground Reactor” might be the solution to provide safety for personnel.

See:

The ground reactor is designed to trip the feed breaker anytime a threshold voltage limit is experienced.

GROUND REACTOR

Reference: RWMA Resistance Welding Manual 4th Edition

A ground reactor is a safety device. It and direct grounding are the two methods of grounding a resistance welding machine. A ground reactor is used to detect over voltage in the secondary circuits of the resistance welding systems especially when direct grounding of the secondary circuits are not practical. A typical application would be a portable weld gun installation. Other applications could include robots, series welding or push-pull welding circuits in multispot welders.

GROUND REACTOR

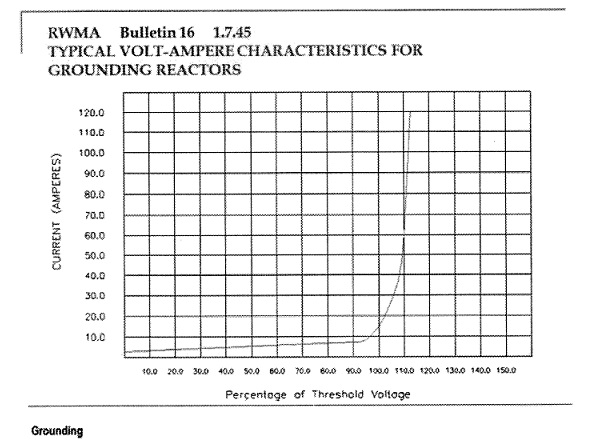

The ground reactor is designed to react to any voltage in the secondary above a predetermined set safe voltage. If an unsafe voltage is detected the ground reactor becomes saturated and immediately provides the secondary a direct path to ground. The secondary current dumps to ground and trips the breaker or fuse at the buss. This ground reactor saturation is demonstrated by the graph below:

GROUND REACTOR % OF THRESHOLD VOLTAGE

The ground reactor can also be an aid when the standard ground wire is overheating and double grounding is not the cause. It could be that circulating ground currents are present. The ground reactors can detect and react to their presence and help eliminate the potential random poor welds these circulating currents can cause.

See:

WHY DOES THE RESISTANCE WELDERS HAVE 112V ON THE FRAME WHEN NOT CYCLING?

Contact your local distributor or machine builder for the proper method to ground new resistance welding equipment.

References: RWMA Resistance Welding Manual- 4th Edition

RWMA Bulletin 16

Roman Manufacturing Inc.

Transformers are very robust pieces of machinery if sized and maintained properly. If not and the transformer fails for some reason, the primary voltage could be transmitted into the secondary coil. This is a serious SAFETY situation and a problem for the machine components. Some secondary components in the machine may not be able to handle the higher voltages. People should be safe since they should not be in contact with the weld parts during welding. Hand held guns would be an exception and could be a safety problem.

To alleviate the transformer short and safety problem all machines are designed to have a direct connection to ground. The transformer secondary/machine is normally grounded. In the case of the handheld gun a ground reactor might be a good option to insure safety.

break

GROUND REACTOR

The main goal of safety is to detect the sudden high voltage and cause a high current to flow to ground and trip the safety devices (fuse or breaker) which will shut the equipment down.

This Personal safety is provided by having a direct ground on the secondary or a ground reactor or other device as described by ANSI/AWS Z 49.1 Section 12.4.6

Other articles that relate to this subject in this blog are:

WHY DID THE RESISTANCE WELDING TRANSFORMERS SHORT OUT BETWEEN THE PRIMARY AND SECONDARY COILS?

IN WIRE MESH WELDING WHAT INSULATION OR GROUNDING STEPS MIGHT BE TAKEN TO INSURE SAFETY?

References:RWMA – RWMA Resistance Welding Manual 4th Edition

American Welding Society – ANSI/AWS Z 49.1 Sec 12.4.6

Roman Mfg.

Constant current is a very useful feature of today’s controls. If this feature is present and you ask for 10,000 amps. The control will deliver that amperage each weld. The control adjusts its conduction and voltage to deliver the current specified. This is considered Conduction Monitoring and may be called C-Factor.

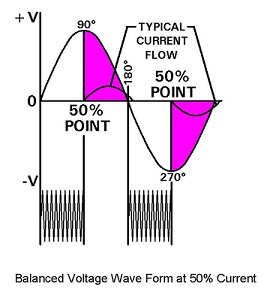

Conduction Monitoring or C-Factor monitor the AC sine wave. Once the proper settings are arrived at and set up in the control an alarm can be set to alert for any deviation. If the control was set at 50% with a plus or minus 10% tolerance, an alarm would be triggered for any variance greater than 10%. The alert does not indicate the cause for the variance. Just that it has happened. Ther cause is usually related to some change in secondary resistance. The normal causes are cables, shunts, misplaced welds, loose connections or shunting currents. There are many other possibilities not listed.

The important question is: What is the weld quality? \Secondly, is there a substandard cable, shunt, connection, water cooling or other conductor??? The electrode overheating is not usually the cause for the alarm. Often current steppers are used to increase the current to match the current increase to the electrode face area increase/wear.

Conduction Monitors can only say something has caused a need for a change in power. The cause must be determined by investigation.

Monitoring the weld nugget quality being produced is always the most important control.

Reference: RWMA - Resistance Welding Manual 4th Edition

A reader after reading the article:

What is the switching device in an inverter?

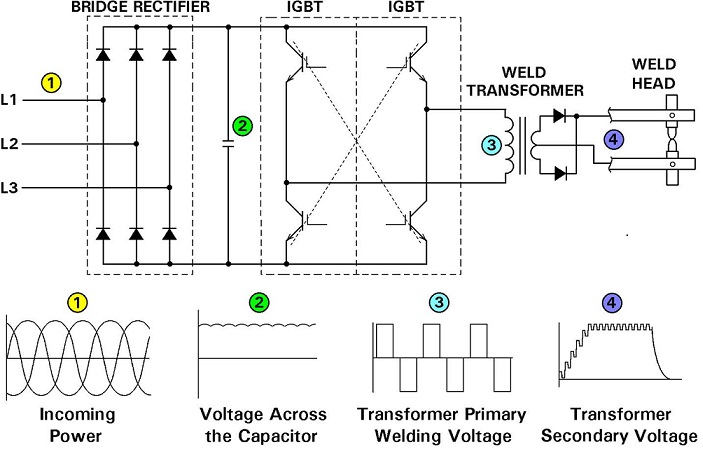

Asked how many times does the IGBT switch per second? The mid frequency direct current controls that dominate the resistance welding market operate at 1000Hz.

The IGBT’s are very fast and efficiently switch at a rate of 1000 times per second. There is an upslope as the current rises from zero to the desired level. On efficient systems this can be as fast as 3 milliseconds. This can be seen in the following diagram. There is a similar downslope.

Conversion In Control and Transformer of Mid Frequency Inverter

This diagram is more fully explained in the article:

The MFDC wave form diagram is not clear

Reference RWMA – Resistance Welding Manual 4th Edition

Page 2 of 40

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.