Controls & Transformers

Questions and Answers

Transformer replacement or upgrading will depend upon the type of machine or robotic gun that is involved. The electrical system and physical systems must also be considered.

PRESS WELDER AND TRANSFORMER

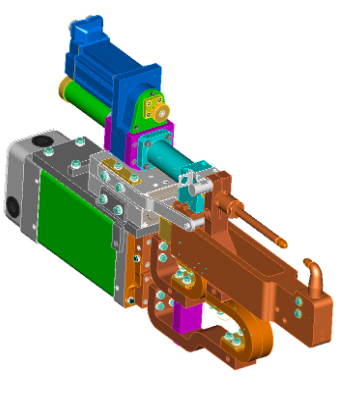

SERVO ACTUATED TRANSGUN AND MFDC TRANSFORMER

The process to change out a transformer varies by machine and application and is beyond the scope of this blog. Consult with local Machine builders and Distributors in your area for the best input on how to replace or rebuild equipment.

References: AWS Standard J1.2 - Guide to Installation and Maintenance of Resistance Welding Machines

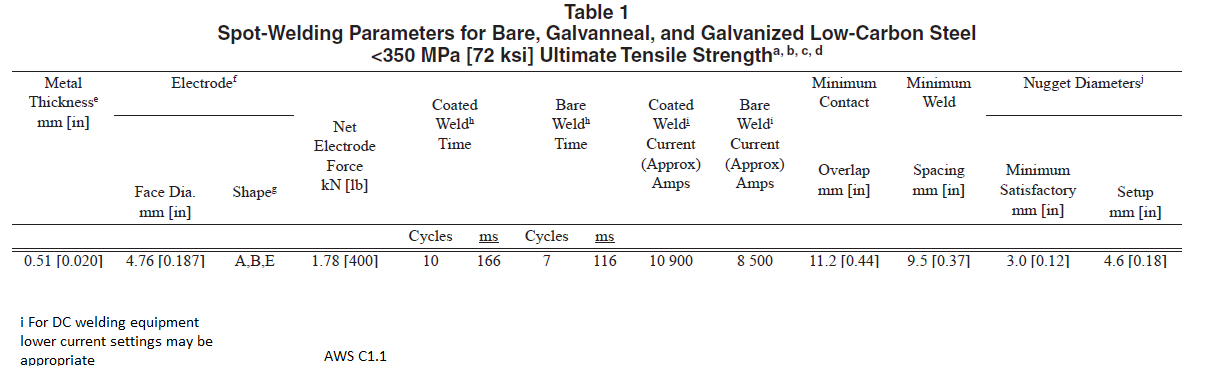

There is no simple way to determine the power for a spot weld job. To determine the power requirements, one must know the approximate weld schedule. Weld schedules are dependent upon the product being welded. For every application one must know the material, thickness and any coating. What are the weld nugget specifications if any. At this point one goes to sources for weld schedules. An article in this blog covers this:

WHERE CAN I FIND WELD SCHEDULES?

Weld schedules will provide an approximate amperage and length of time for current flow. As discussed in the above article many other critical data are provided necessary for set up including electrode selection, force and resultant weld nugget. These schedules do work.

With the amperage and time and the number of welds per minute and parts per hour one can back into the duty cycle and power. With the weld schedule and the data just mentioned you could read the article:

HOW DO YOU SIZE A RESISTANCE WELDING TRANSFORMER?

The current values and data found in the weld schedule are used here to calculate the transformer size. With the transform determined the appropriate machine can be chosen to weld the product.

One can always turn to local machine or transformer suppliers and they can help with evaluations and give guidance.

References: AWS C1.1 Recommended Practices for Resistance Welding

RWMA – RWMA Resistance Welding Manual 4th Edition

CMW Resistance Welding Products Catalog

Tuffaloy Resistance Welding Products Catalog

This answer has been given in the reverse mode in another published article:

HOW MANY PRIMARY AMPS WILL A 64 KVA RESISTANCE WELDING TRANSFORMER PULL?

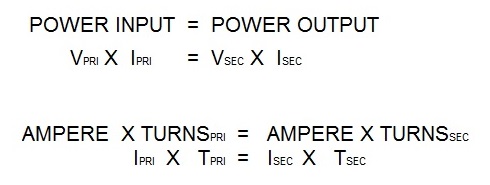

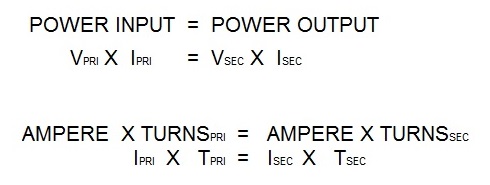

If you look at this referenced article, several important data points are necessary in order to calculate the output of the 10 KVA transformer. The turns ratio being the first. The turns ratio shows that power in the primary equals power in the secondary. Secondary voltage is a second necessary data point.

The actual current will be influenced by the secondary circuit.

If you know your turns ration and primary amps at least an estimate can be made. If you measure the input versus the output voltage you have an estimate of the turns ratio for that set up. If there is a tap switch on the transformer one can change the secondary voltage. Then all of the calculations change. Do study the above document so that duty cycle and all factors are considered.

For additional assistance contact a local equipment manufacturer or distributor.

References: RWMA - Resistance Welding Manual 4th Edition

This answer has been given in the reverse mode in another published article:

HOW MANY PRIMARY AMPS WILL A 64 KVA RESISTANCE WELDING TRANSFORMER PULL?

If you look at this referenced article, several important data points are necessary in order to calculate the output of the 10 KVA transformer. The turns ratio being the first. The turns ratio shows that power in the primary equals power in the secondary. Secondary voltage is a second necessary data point.

The actual current will be influenced by the secondary circuit.

If you know your turns ration and primary amps at least an estimate can be made. Do study the above document so that duty cycle and all factors are considered.

References: RWMA - Resistance Welding Manual 4th Edition

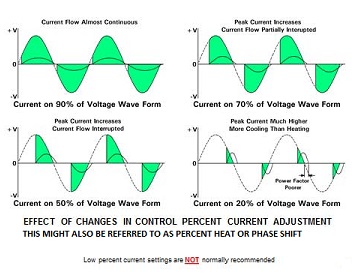

The SCR contactor is a component of the AC resistance welding control. The control initiates the time and frequency of the SCR’s activation and passing of current. This current of course goes to the transformer primary and is converted to low voltage high current in the secondary of the transformer to travel to the electrodes and make the spot weld. The SCR is the on off switch for this process. It functions on every half cycle of current as instructed by the control.

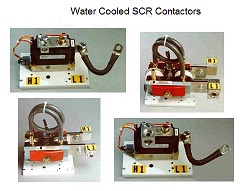

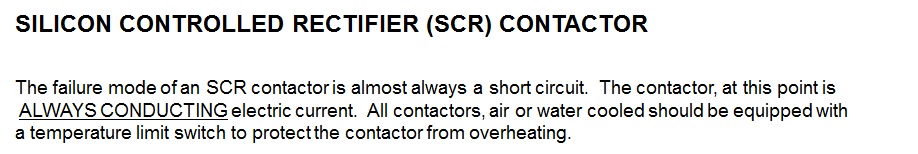

The SCR contactor is a solid state device with no moving parts. It is very fast and reliable. As with all electronics it is sensitive to heat and must be cooled by air or water depending upon its service rating. A temperature limit switch is recommended.

If one of the two SCR’s has failed as noted above, it usually fails in the on mode, The transformer will be under full power. The control will not see this. If activated the electrodes will get VERY HOT. The circuit breaker may trip?

Test voltage across the electrodes when open if they have voltage the SCR has failed.

Sometimes SCR’s don’t short out and trip the breaker. Occasionally they fire erratically. If only one SCR fires, this is called half cycling. The transformer is out of balance and will make a grunting sound, vibrate, current will spike and the breaker may trip.

Generally, a failed SCR leads to voltage when there should not be any at the electrode. The second less frequent events are strange erratic happenings, sounds and tripped breakers. If you are not sure what you are dealing with make a call to your local equipment supplier or distributor who likely has dealt with this situation before.

Reference: RWMA Resistance Welding Manual 4th Edition

Page 5 of 39

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.