Flash and butt welding both use the work piece as the electrode. They both use a clamp to hold the parts and apply force. The entire cross section of the work piece is welded. It is in the timing and application of force and current that they differ.

In butt welding the parts are clamped brought together under force and then current is applied. The parts heat due some arcing and to Joule H= I2rt heating. The joint gets hot upsets and after cooling the force is removed. The result is a strong butt joint.

Butt welding is more sensitive because the surface of the part coming together decides the current flow pattern and where the heating will occur.

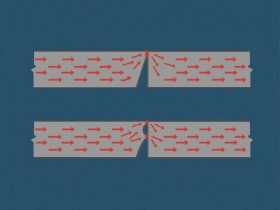

If the part is cut unevenly or is rough the current will flow through these contact points. These points will carry all of the heating until they collapse or are overheated and expelled. Then new contact points will make contact and join the heating process until the current ends. At this point there may be a bond but it may be only a partial cross sectional bond or none at all.

Butt Weld with Uneven Current Flow

Reference: RWMA, Resistance Welding Manual. Section 5