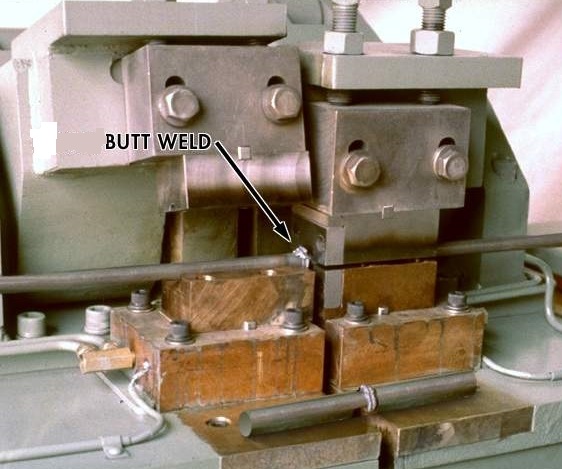

Copper, aluminum and steel wire and rod are frequently butt welded in industry in order to form large coils for drawing down from large gage diameters to smaller gages. This reduces handling and costs.

STEEL ROD BEING BUTT WELDED

The question is where can one find a butt weld schedule for this process? AWS C1.1 “Recommended Practices for Resistance Welding” lists one schedule. It is for Aluminum 1.6 mm Thick (0.063”). There is nothing readily available for rod or wire.

To solve this issue one must turn to trial and error.

To do this a controlled experiment will be set up with the parts on the butt welder to be used.

The first step is to Get the machine ready for operation. Maintenance may need to be performed on the equipment. Definitely the equipment condition needs to be evaluated. This evaluation can be performed by following the steps outlined in AWS J1.2 “Guide To Installation and Maintenance of Resistance Welding Machines”.

When the machine is ready to operate then it is time to prepare samples for testing.

Prepare Samples *

Clean up the Butt Welder

Prepare tooling – Clean up and align properly

Make sure tool will grip the part properly

Set transformer tap, control/power supply to lowest settings

Adjust force – clamping force should be at least twice the forging force

Forging force will depend upon material being welded and its diameter?? and your machine capability.

Try a dry run without power??

What happened

Did the part slip? More clamping?

Too much forging force?

Adjust

At lowest power/ON run the first sample - What happened?

No weld ?

Adjust time or power or tap up modestly, try again

What Happened? No Weld

Repeat till a satisfactory butt weld is achieved.

THIS IS TRIAL AND ERROR – The secret to every successful process

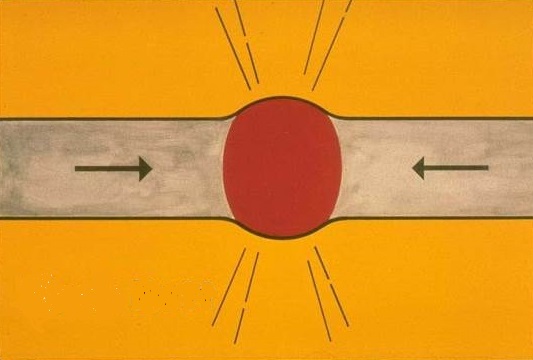

SCHEMATIC OF A BUTT WELD

With a good weld schedule that works record all of the variables on the weld schedule sheet take a photo of the set up and start production.

Reference: AWS C1.1 - Recommended Practices for Resistance Welding

AWS J1.2 - Guide to Installation and Maintenance of Resistance Welding Machines

RWMA – Resistance Welding Manual 4th Edition

*Important many machine set up steps were not have been listed here. This was meant to demonstrate the sample testing starting at low power settings and adjusting up to higher satisfactory levels.