Spot Welding

Questions and Answers

That is an interesting question. Stainless is highly resistive and won’t conduct heat too far or fast but the plastic is only 3 mm away.

My gut says without some sort of extra cooling the plastic is likely to see some heat. I trial run is needed.

Is water an issue? Put a mist of water in the weld area as the part welds, similar to a seam welder just less water. Initiate the mister with the weld cycle.

Make sure the electrodes are cooled well to reduce time at heat. Minimized the size of the weld and weld nugget. Keep the electrodes in place after the weld to pull heat out.

GOOD LUCK!

Mechanical properties and chemical composition of the workpiece have a potential great affect upon the weld quality. Let’s examine this one at a time.

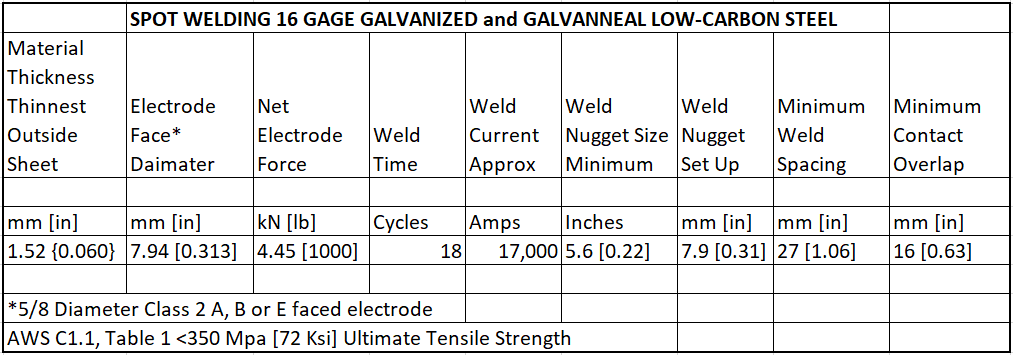

For each new resistance welding job there will be a known weld schedule or one must develop a weld schedule. For simplicity we will assume there is a known weld schedule. The data generally supplied is the electrodes and related tooling to use. The data may look like the chart below:

After researching this product on the web, I found that Weld Aid is a chemical product sold in several forms. Mostly liquid for precleaning industrial metal products. Some cases it is used to coat tooling and fixtures to reduce weld splatter from adhering. There is also a version to preclean wire fed into Mig welders.

As to using this product in a resistance weld joint? You can try it of course.

I see not benefit and it would not be high on my list of experiments.

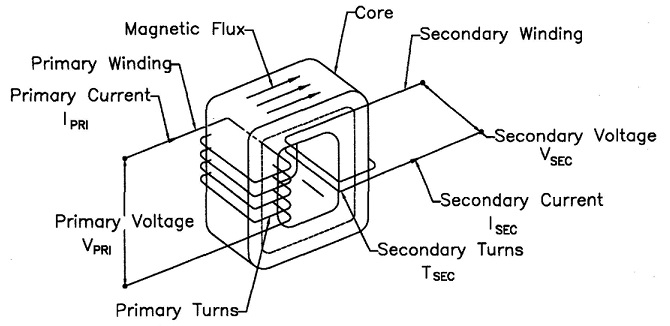

To answer this question I will demonstrate the calculation of the turns ratio for a AC 16 KVA resistance welding transformer.

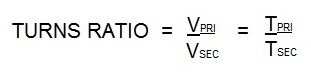

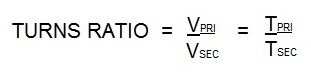

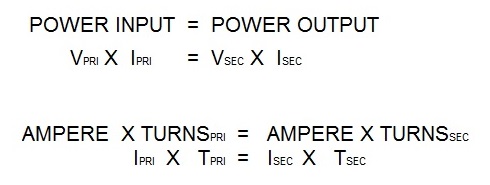

The turns ratio for all resistance welding transformers is calculated in the same manner no matter the KVA size. Turns ratio is the ratio of the number of coil turns in the primary vs the secondary.

In AC transformers, there are many turns in the primary. The secondary has one turn. If there are 50 turns then the ratio is 50/1. Therefor the primary voltage will drop from 220V and 100 amp input to:

220/50 = 4.4 volts in the secondary. The equations for this are:

Vpri = Voltage on the primary Tpri = Turns in the primary coil

Vsec= Voltage on the secondary Tsec = Turns in the secondary coil

Power into the transformer will equal power out of the transformer

Isec = Secondary amperage Amperage Ipri = Primary amperage

In the secondary using the above formula:

If the Ipri = 100 amperes

If the turns ratio = 50/1

Isec = (Ipri X Tpri)/ Tsec

Isec = 100 x 50/1

Isec = 5000 amperes

There are several additional articles written on turns ratio available in the “HOW TO RESISTANCE WELD” blog.

Enter “Turns Ratio” in the search box on the home page for additional information.

Reference: RWMA Manual Chapter 19

Page 8 of 47

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.