Seam Welding

Questions and Answers

The actual surface temperature will depend upon the weld schedule being used and the method of cooling. Is this a fluid tight seam weld or a roll spot seam weld? Is flood cooling used or not? What is the speed of the seam welding? These and other factors will have an effect upon the heat being generated and its build up. Steel no matter the thickness must reach the same temperature to weld. The thickness does dictate how much total heat is input and must be removed.

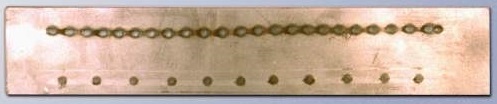

ROLL SPOT

,

CONTINUOUS SEAM - FLUID/GAS TIGHT

To address this question we will assume that we are making a liquid tight seam weld. This applies to any thickness of material. Many of the conditions listed below are common to spot welding. In seam welding the welds overlap as the weld wheels roll forward. In a seam weld the process current is developed to allow for shunting current through the trailing welds which have already been made.

INTERFACE EXPULSION SURFACE EXPULSION

Either interface or surface expulsion can lead to burn through.

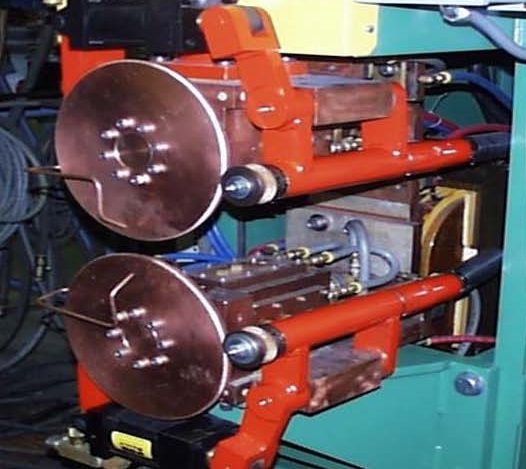

There are two types of drives for seam weld wheels. One is driven by the central hub, direct drive. The other is driven by knurled wheels riding on the perimeter of the seam welding wheels, indirect drive. There are pros and cons for both systems.

Another article in this blog discusses the differences:

HOW ARE SEAM WELD WHEELS DRIVEN?

Here we will address direct driven seam weld wheels. The question is should one drive

• Both wheels

• One wheel

• or maybe none

A seam welding shaft is generally a large diameter copper alloy bar precision machined to conduct the current deliver force and rotate during the seam welding operation. The shaft works hard under heavy duty cycles, currents and forces. The shaft operates in a housing which is filled with conductive grease and has current carrying shoes which ride on the shaft to deliver current. Eventually these conductors and the shaft wear and service is required.

Shaft wear is more common than breakage but is possible.

SEAM WELDER WITH KNURLERS

Some information for seam welding high nickel chrome iron alloys is published by the American Welding Society in their Welding Standards. Examples of current values that can work are exhibited there.

AWS Standard C1.1:2019 “Recommended Practices for Resistance Welding”

Page 3 of 15

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.