In the past most flash welders were AC. AC controls are relatively inexpensive compared with DC or mid frequency (MFDC) controls. If you have AC equipment and power is not an issue it would be logical to use AC if possible. AC controls with SCR’s are very robust and will operate for many years.

Flash welding requires a lot of power. If the power requirements exceed AC’s practical capability, then DC or MFDC become the proper choice. DC by its nature is rather large equipment. In the last few years Mid Frequency power supplies have entered the market. Initially they had a problem with the spikes associated with arcing. This has been worked on and now MFDC can be used for flash welding.

The question raised is about an 18V/9000Amp application. There are 17V secondaries in use with MFDC. Yes, 18V/9000Amp is a workable MFDC application.

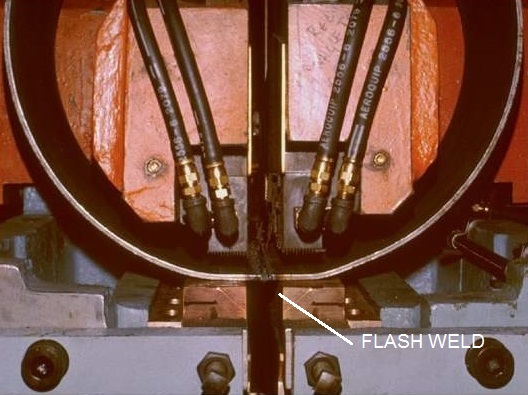

FLASH WELDER

Compared with an AC application MFDC will reduce the power requirement substantially and could become economically advantageous over AC. MFDC also offers very fine control of the actual weld cycle which can be helpful. MFDC controls can result in higher quality levels and more good parts.

If you were considering the need for DC equipment, MFDC may be a better choice because it delivers the DC current, reduces the total plant power load and reduces the size of the flash welder transformers.

Ref: RWMA Resistance Welding Manual Section 5